The Bigger Picture Of Our Smaller Components

Sedimentation, Part 1

Natural Sedimentation

In these everchanging times of life, we often take for granted our most vital components of life. Processess that produce the most essential basis of life it taken for granted daily. The next world war will not be fought over land or for power, but rather for clean water. We must understand that 70 % of Earth is covered by water, but only 2.5 % of that water is healthy for consumption. This post is to only identify this problem, but to also elaborate on the processes that allow us to be provided with clean, sanitary water. This process is that of Sedimentation.

Sedimentation is a process that refers to the deposition of molecules that are either in solutions, or particles that are in suspension, in response to an external force applied to this clump of material such as gravity, is centrifugal field or even an electric field of force. Sedimentation is an important process around the world due to its versatility in application, as this process is applicable to various sizes of objects, from the suspension of dust as well as pollen particles to the minute cellular suspensions to solutions of certain single molecules such as proteins or peptides, which are enormously smaller than the aforementioned.

Separations often occur with two miscible or immiscible phases. Separations can occur between solid-solid interactions, solid-liquid interactions as well as liquid-liquid interactions. It must be noted however, that the most important form of separation is that of solid-liquid interactions. The reason for this is due to the fact that in industries around the world (and even occurring naturally), solids and liquids tend to mix and form immiscible solutions more greatly than that of the other two situations. It is due to this reason that a lot of investigation and practicality was put in to research methods in which solid and liquid separations could be possible. The methods that were found to facilitate this form of separation are mainly used in:

- mineral processing

- as well as the important process of water purification.

Mineral Processing:

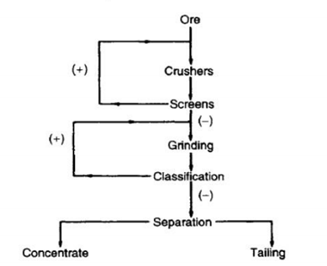

Material processing is the conversion of raw ore to valuable handling product. A simple explanation of the process involves the run-of-mine ore which undergoes the process of comminution, followed by the separation methods (such as sedimentation) followed lastly by product handling.

To enter the more intricate details, we must familiarise ourselves with the different methods of separation that occur before product handling can occur. These processes include:

- Crushers- creates multiple smaller components of a once large single component

- Screening- removes the smaller particles from the products of crushes

- Grinding- two large components are forced together upon acting forces in which these components break into smaller pieces

- Classification- end products are identified and grouped by specific factors such as size or percentage moisture present in the component

Once these processes are accomplished, the product can be separated according to whether it is identified as a concentration or tailing.

Water treatment:

Water treatment is one of the most important processes available to the world in our present. These fundamental methods allow us to be provided with clean and sanitary water, and allows for civilization to prosper forward.

The water purfication cycle

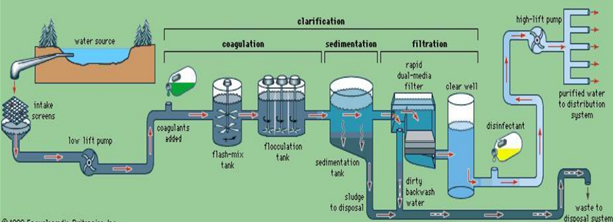

The water purification method does not only include sedimentation, but also consist of two further methods known as coagulation and filtration. These two methods, along with that of sedimentation, forms the basis of the water treatment process and is referred to as clarification.

The process begins by capturing a water source, often available from rain or other methods, and processing these liquids, firstly, via an intake screen. This is done to remove the particles that are large enough to be seen by the eye. The product of this initiating piece of equipment is transferred (via a pumping system) to the first step in the clarification process. It is at this point that coagulants are added to this liquid stream. Due to the sudden addition of the coagulant, an aggitative process must occur to allow for proper mixing of these two liquids. To facilitate this process, the stream then passes through a flash mix tank, and is then passed through a flocculation tank (these processes will be explained next). The product exiting from this tank is the final product from the coagulation process.

The next process to occur in the clarification process is referred to as sedimentation. The now miscible mixture, made possible by the previous process, is allowed to remain a rest. This allows for clean water to be separated from that of “dirty water”. The presence of dirty water is possible due to the previous process. Once most of the original mixture can be separated into clean and dirty water, they are separated. This then brings us to the end of the sedimentation process.

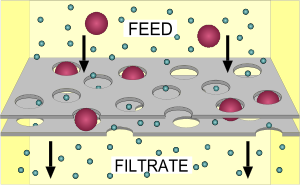

The last process in that of clarification is the filtration process. This process consists of two pieces of equipment, namely a form of filter (such as a rapid dual-media filter) along with a clear well for storage. The clean product that exits the sedimentation process is then fed into the filter. In this piece of machinery the water is further processed to remove the excess sludge from the clean water, which was not removed in the previous step. When separated from the clean water, the dirty backwash water is fed into the same stream as that of the dirty water from the sedimentation tank, while the clean water is transferred to the clear well. In this well, the water is observed and further treatment may be applied if necessary. The water from this well is then transferred along the pipeline via a pumping system. This signifies the end of the filtration process as well as the end of the three-part clarification process.

The clean water that exits is then treated by a disinfectant as the last measure of treatment. The water is then known as purified water, and is then distributed where necessary. The contaminated water that was captured from the sedimentation tank as well as the filter media is sent to a waste disposal system, whereby a small percentage of the water would be regained via more intensive treatment methods.

Coagulation and flocculation

Coagulation and flocculation are two commonly-used terms in the sedimentation industry. These processes form the basis of purification of our most important resources. Coagulation is the accompaning process of which occurs when a coagulant is added in a body of water whereby colloidal suspensions occur. Colloidal particles possess a negative charge and us form non-ideal ionic solutions. Coagulants the solution to this problem as they neutralize the cationic charge as they are positively charged ions.

A metaphor to elaborate "clumping" of similar property products- Flocculation

Flocculation on the other hand, does not at all involve chargers but rather involves the geometry of particles. Flocculation is a process in which polymers are added to a solution in order to clump up the smaller, unstable particles together. Due to this process, larger aggregates of these particles are formed. This ensures that the once smaller particles are able to be removed from his solution and thus produces a higher quality product. As aforementioned, and now reconfirmed, flocculation does not involve any form of neutralization of charge but rather a form of physical process of separation.

A water droplet

This brings us to the end of my first installment on the importance of Sedimentation. I hope that i was able to underline the importance of the processes that allow us to go about our daily lives the way we do. We should be thankful of the modern forms of technology that allow us to be provided with such pure products.

Images are linked to their sources in their description

The End

References:

[1] https://en.wikipedia.org/wiki/Sedimentation

[2] https://www.iwapublishing.com/news/sedimentation-processes

[3] https://www.britannica.com/topic/water-purification/imagesvideos

[4] Unit Operations of Chemical Engineering by McCabe W.L.,Smith J.C. And Harriot P (McGraw-Hill, 7th edition, 2005)

[5] https://en.wikipedia.org/wiki/Mineral_processing

[6] https://en.wikipedia.org/wiki/Water_purification

[7] https://www.sswm.info/content/coagulation-flocculation

[8] Coulson and Richardson's Chemical Engineering Vol. 2, Oxford, Butterworth-Heinemann by Richardson, J. F., Harker, J. H., Backhurst, J. R., & Coulson, J. M. (2002).

[9] https://www.multotec.com/content/mineral-processing

[10] http://www.slideshare.net/SyedTanveer3/mineral-processing34661757

Read more about water filtration here https://www.topwater.ro/blog

Here you will find articles written by professionals in the field of water filtration systems, on how to remove limescale from tap water used anti-limescale filters for household use. In this blog we aim to bring you fresh information about the things you need to pay attention to before buying a water filter.

Congratulations @akeelsingh! You have received a personal award!

Click on the badge to view your Board of Honor.

Do not miss the last post from @steemitboard:

SteemitBoard World Cup Contest - Semi Finals - Day 1

Participate in the SteemitBoard World Cup Contest!

Collect World Cup badges and win free SBD

Support the Gold Sponsors of the contest: @good-karma and @lukestokes

your image links don't link directly to the image page with all the copyright information. Please change this for future posts.

Congratulations @akeelsingh! You received a personal award!

You can view your badges on your Steem Board and compare to others on the Steem Ranking

Vote for @Steemitboard as a witness to get one more award and increased upvotes!