Rebuilding the Barn Doors January, 2019 @goldenoakfarm

The doors on the East end of the barn had seen heavy use over the years and had started to come apart. The one on the right was the worst. It had lost the holder to latch shut and we were using pigtails to keep the doors shut, in this photo of January 2017.

Just after the first of the year this year, we had a windstorm, and the stakes and buckets holding the doors shut failed. The right hand one blew off. It was imperative we repair it as soon as possible, as we are a real wind tunnel out here, and the animals in the barn needed the protection.

This left side door was not so bad. This shows the construction that kept these doors functional for over 100 years. They had used square cut nails, clinched over.

So my husband contacted the little sawmill owner up on Horse Mountain and ordered the wood he’d need to rebuild both doors. This sawyer puts out quality wood, properly sticked, and my husband said it was a joy to work with such straight wood.

He rebuilt the right one first, as it was the key to keeping both doors shut. The central bar had a support on the oppose post that kept the doors firmly closed.

The Z bracing assures the doors stay square. Having double Z bracing means this door might last 100 years like the last one.

The right side hung, but no latch support, so the bucket is doing the job.

The bar on its support

Close-up of bar and support

Left side door built.

Because the wood was so straight, it did not need battens as the old doors had.

Both doors built and hung, but no latch or latch support installed yet, so he used a heavy bucket to keep them shut.

To finish the job, he re-installed the conveyor belt bottoms. These allowed the doors to open in snow, but kept the wind out.

Conveyor belt on the right side, and the latch opener hanging ready.

Finished: belts on bottoms, latch on, latch support on, latch opener (from the inside) in place, bar and bar support working. He used all the old hardware, just replacing bolts as needed.

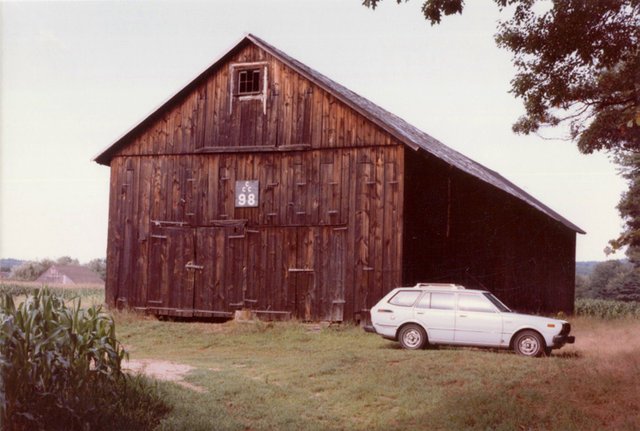

Our 150 year old tobacco shed, Consolidated Cigar Co #98. We need to refurbish the sign.

The shed when we bought it in July 1983.

Congratulations, your post has been selected to be included in my weekly Sustainability Curation Digest for the Minnow Support Project.

Editor of the The State of Steem SoS Daily News.

Promoter of The State of Steem SoS Weekly Forums.

Editor of the weekly listing of steem radio shows, podcasts & social broadcasts.

Founder of the A Dollar A Day charitable giving project.

Thank you!

you all are so handy! I love it! I guess it's all in having the right tools ;0)

That, and in this case, excellent materials. Also decades of practice. :))

wow nicely done - wonder how long until new farm owners start to look for barn doors on ebay before doing it local :P ... what kind of sealant did you use on the wood?

It's not cost effective, if you have the work done, to have them source and build local. But if you can do it yourself... :)) Those 2 cost about $100 total, I think.

The old doors, made of the same wood, lasted 100+ years with no sealant. Hopefully these will also.

Being able to do it yourself makes a big difference! Nice job!