My Knives #19 Jamaica Theme Redemption Chopper ️️️🌎 😰

Won't you help to sing

These songs of freedom?

'Cause all I ever have

Redemption songs

Redemption songs

Oh, I didn't see you there!

Khm, khm!

Hello dear Steemians,

In this story I'll be presenting a custom build I did for a great guy who is a Jamaican chef living and working in London.

London babe - finaly

You may think, wait a second there Doc, this knife looks awfully familiar. And you would be right.

Before you get overwhelmed with disgust and unfollow me for recycling, just gimme a sec to explain.

This knife does look a bit familiar because she was a perfect bitch and I have talked about how big of a bitch in one of my previous posts.

For the lazy ones who just can't be bothered to click on a link, let's just say it took me three tries to actually finish her, because she kept breaking in the quenching.

Anyhow, it all started with Anthony asking if one of my knives would be a good choice in his kitchen. It was actually the one none of you wanted to buy - this one.

So I've asked him - What do you actually need the knife for?

And he told me he would like a knife that could both be used as a chef knife and chop through the whole jerky chicken.

Now, if you know anything about knives, you'll know that making a knife that's good at different tasks is a knifemakers nightmare. I won't go too deaply into this topic since I've covered it in various posts before (sorry no link - now I'm lazy), but I'll explain why it's a pain in the but on this case.

Let's start from the beginning: a chef knife is a knife that has to cut like a laser. To achieve that it has to be ground as thin as possible. To give you a perspective my "top-shelf" gyutos are ground so they are around 0.7mm one cm above the edge (I have no idea how to conver that into imperials so I won't).

This is what such a knife looks like from the choil

This will fly through onions like they don't exist, but if you take an edge that thin and try to chop a bone, even a chicken bone, it will break. It just doesn't have enough support for chopping through bones or trees or anything like that. It was made for slicing vegetables and cutting boneless meat.

In order to have a knife that can chop a bone, it has to be quite thick at the edge. Just think about what is the best tool that you can think of if you want to chop bones - a cleaver right? Well, that's just an axe with a fancy name.

So when you get down to the bones (see what I did there) he was asking me to make him a super thin axe. Well, that just can't be done.

After thinking about how to get out of this nightmare, I did realize I could try to make a kind of a hybrid - a knife that will have compound geometry and be thin on one part of the blade and thick on the other. That's far from a perfect solution but it was the best I could produce from my brain.

Just to mention, I had no idea at the time how to actually do something like that.

I gave him a few suggestions and a few design ideas, and after a while, he added another cherry to my, already full, plate.

He's a Jamaican and it would be super cool if I could make the handle in the Jamaican flag theme.

Well, the order just stopped being a nightmare and became just too ridiculous for me to pass out an opportunity to make my life a living hell.

So, I said - Yeah, why the hell not I'll make you the knife

And that is how one of the biggest bitches started her life and made mine an indescribable misery.

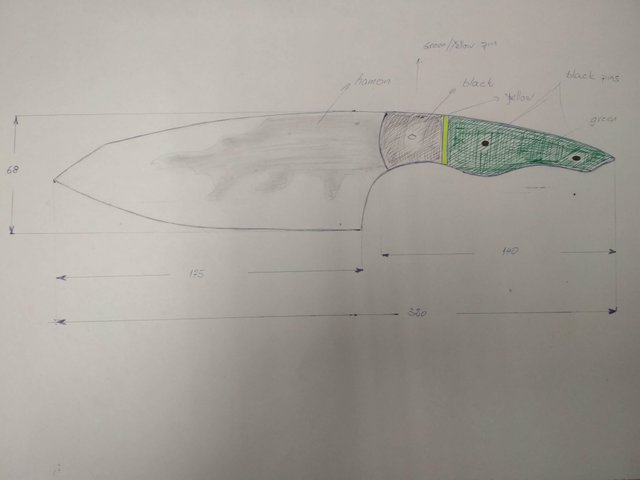

A few stats before we start the picture show

The knife was made in 1095 steel, and since the bitch broke two times before I ran out of the clay I use for my hamons, I was forced to do an edge quench.

So, it is a differentially heat treated but with a twist.

The handle part of the nightmare is compound of black & green G10 scales, yellow spacers, one green G10 pin, and two carbon fibre tubes I actually filled with died epoxy.

The ground is compound - the heel of the knife is much thicker than the tip, and it is convex that gradually becomes flat in the same direction.

The Blueprint

The Build

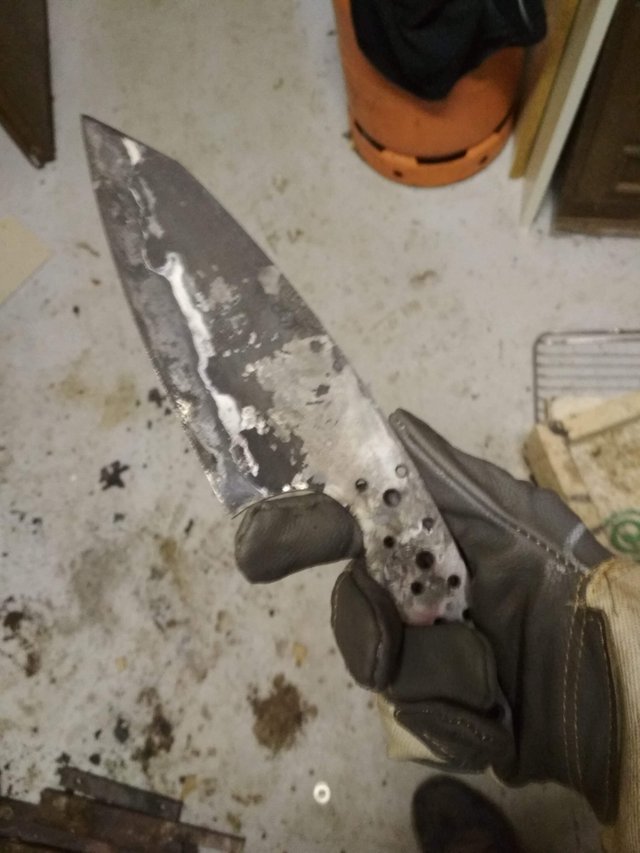

The fails

Finally a sucessful quench

Roughr grind at 40 & 60 grit and a test etch

The handle materials

Some hand sanding

Dry-fitting the handle and gluening thing up

Profiling the handle

Finaly done

The final product - it was a bit cloudy so the colours are not that great

Final thoughts

For someone who hates custom builds, I do seem to get stuck into lot of them.

Could it be that I actually like making myself miserable???

Anywho, thanks for stopping by and if you have some impossible knife that you would like to have, apparently I am a guy to talk to...

Let's see, third or fourth time is a charm, eh @docsmith?

You categorize it as liking to make yourself miserable, I'd call it, gutting it out. Taking on a challenge and just making it happen. Hulk stomping your way through building a knife.

One man's misery is another man's triumph, I suppose.

Still, it looks good. Did you test it to see if it does what it's supposed to do?

Or is testing a knife not something you do? Probably protocols for that, too, but I can't remember if I've heard about them yet.

@glenalbrethsen

Third time this time, but it's not a record I did have a custom order that took me 4 quenches to get it right :)

I actually don't mind the challenge of a custom build or trying new stuff. What I generally dislike is the pressure and the stress which come with this kind of builds, because they kinda take the fun out of making knives. And I want my hobby to be pure fun.

Furthermore, with a build like this, there is an additional problem: what if he told me that he doesn't like the knife after it was done? It's hard enough to sell knives as it is, it's almost impossible to sell one that was made by someone's personal preferences.

I'm not into knifemaking for money, but those couple of $100 I get for a knife keeps my shop running and enable me to buy materials I need to make them. Seeing how this one was such a bitch and kept breaking, I didn't even break even with her. So if he decided he didn't want her that would set me back quite a few steps.

Testing, oh yep, I do test my knives. And I make test knives. This one did quite well. It's not a knife I would like to have in my kitchen but every knife is a compromise.

Your craftsmanship was amazing, I came to ur page because @goodforsoul used one of ur knifes. Personally I'm not a fan off bug and sharp knifes for accidents but I can appreciate the aesthetic, I love the shape and the craft of making it in general. Real 😎 cool

Well, thank you for stopping by and for your kind words.

But, I just can't let this slide, how can you both enjoy cooking and not be a fan of sharp knives? A dull knife in the kitchen is way more dangerous than a sharp one. ;)

medium sharp is okay, sharp is okay if its a small knife. I used a brand new large knife just recently an almost lost the tip of my pinky finger. Thanks to the nail protecting it i just came a way with a deep cut but it was bloody painful, the thing i was chopping was wet and the knife slipped somehow! i dont need super sharp as im vegan. im not cutting any meat. Im a silver smith as well so i appreciate the technique of working with metal :)

Hello @docsmith, thank you for sharing this creative work! We just stopped by to say that you've been upvoted by the @creativecrypto magazine. The Creative Crypto is all about art on the blockchain and learning from creatives like you. Looking forward to crossing paths again soon. Steem on!

Thanks guys - much obliged!

This post was shared in the Curation Collective Discord community for curators, and upvoted and resteemed by the @c-squared community account after manual review.

Thanks guys - much appreciated 👊

But it's still not an English lady, lol :D But at least you got closer now.. the knife goes to London! It is a brilliant piece!

I have a question for you.. do you know if it would be possible to import it to Switzerland? My husband always wanted to have a chef knife and since Christmas is coming ;) This would be such a unique piece.. If you think it could be delivered to Switzerland you can contact me on Discord and we can discuss further: delishtreats#6850

It would be a treat for him! ;)

Have a great weekend!

English - I'm getting there 😂

Thank you, I'm at my shop now so I can't go to Dicord, but I'll drop you a note when I get home.

Also, shipping to Switzerland is no problem...

Cool! I'm not sure if I'll be able to get to you today or tomorrow as I'm traveling but just bear with me :)

Amaaaaaaaaaaazing amazing amazing <3 I love how detailed and beautiful and personal your knives are <3 ... and your final thoughts XD

I'd like a knife one day, maybe !!! And I'll think of you !!! <3

Thank you 😆

Again a great proof of your amazing craftsmanship. How you master to bring old smith's tradition and modern design together!

Tnx - I don't know that I'm a master but I do try 😂

Nice work! I'll give you a shout when I'm ready!

Thanks - will keep you on my mind 😎

Howdy sir docsmith! lol..I think you just like the challenge. Did that chef like the knife? It is thick on the handle end and then on the half toward the tip is that the design? I think it's gorgeous!