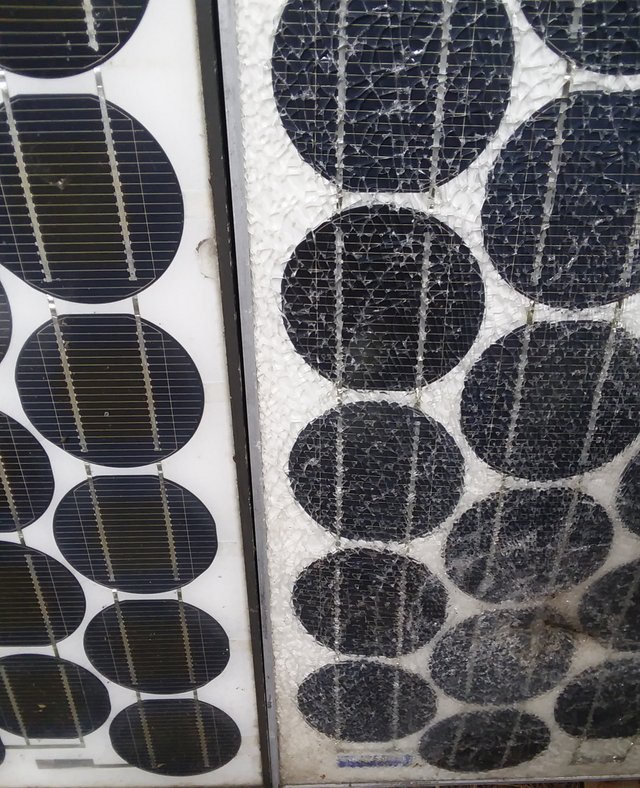

How to fix broken glass on a solar panel.

The first step was to lean the panel on some sawhorses and angle it towards the sun so that I could use a multi-meter to check the open circuit voltage of the panel.

The open circuit voltage and other specifications can be found on the back of the panel. The label on my panel states that it has an open circuit voltage of 46 volts but the manufactures website says that the open circuit voltage is 44.6 and while this discrepancy does not really matter to me I find it worth noting. The actual voltage that I got from the panel was 43.4 volts which could be due to the shattered glass and because it was cloudy outside when I was taking the voltage reading.

The next thing that I did was to position the panel on top of a pair of sawhorses that had a plastic pallet resting on them which made it just wide enough to accommodate the panel's width. This particular panel is nearly six feet by four feet.

I then used a level and some small pieces of wood to level the panel in all directions.

I then used denatured alcohol and a sponge to remove the larger accumulations of dirt and any loose pieces of glass. I also used the sponge to thoroughly scrub where the glass meets the aluminum frame. Do not use a scrubbing pad to clean the glass because it will cause scratches.

I then used paper towels and denatured alcohol to remove any remaining dirt and repeated this process until the paper towels came away more or less clean and did not appear dirty after wiping them across the glass. Be careful of heavily pitted areas and small shards of glass during this process. Also do not press down hard while wiping the glass because it could further damage the panel.

I then used more paper towels to remove as many streaks on the glass as possible that were caused by the cleaning process itself.

I used a coffee can to pour the denatured alcohol onto the sponge and paper towels over and then tossed the paper towels into it when I was done with them so that I could later burn them.

Next came the actual sealing process which in this case I used a water based polyurethane intended for indoor use and a wide plastic putty knife but I highly recommend that folks use an outdoor polyurethane and either a paint brush or roller to apply the polyurethane evenly and work it into the pits and cracks. You can also use epoxy to seal the glass but it is more expensive. There is even an epoxy made explicitly for solar panels.

I just poured the polyurethane from the can a little at a time and then spread it evenly with the putty knife over the glass and was extra meticulous with working it into the heavily pitted areas and also along the edges where the glass meets the aluminum frame. It is better to apply several thin layers than to apply a single thick layer and you should expect a minimum drying time of two hours between each layer.

It started to look like it was going to rain so I only got a single coat of polyurethane applied today before putting the panel away in the shed but hopefully I will get a few more hours of bright sun tomorrow so that I can add another coat. I have a one quart can of polyurethane and am planning to just keep applying coats of it until I use it all.

Moral support dog is optional.

The voltage is close enough to tell me the panel is still good.

)

)

Great, I think you can claim some evergreencoin

https://evergreencoin.org/proof-of-environment/

Thanks @solarcoach!

Congratulations, your post has been selected to be included in my weekly Sustainability Curation Digest for the Minnow Support Project.

Compiler of the Homesteaders and Preppers on Steem list.

Compiler of the Homeschoolers & Unschoolers on Steem list.

Thanks @pennsif! I am glad you liked it!

I have never had to do this with my panels, but it's good to know it's possible.

Yeah @tdre it was the first one that I did as well. If I had known how easy it was I could have had ten identical panels to repair. My friend found them at a scrap metal yard and since I did not know about how easy it was to repair them I had them only pick me up one instead of all ten. It cost thirteen dollars USD for one 325 watt panel and all ten would have only been 130.00 USD!

Awesome! Thanks for including so many pictures. I would say that moral dog support is essential!

Haha yeah about the dog! The pictures took forever to upload! I am slowly getting better at taking them while I am doing stuff though!

It's hard to stop a project to document it, but it's really helpful for those of us who are just winging it! Thanks for taking the time. And the patience.

Posted using Partiko Android

You are welcome @goat-girlz! I am also just winging it so there is that! It is definitely tricky to do the documentation of projects. Most of the time I just wish that I had a good assistant that can take notes and pictures (or record video) while I am doing stuff. It is a lot to juggle and I admire those that do it well.

Wow absolutely amazing and definitely going to have to submit this for some love as well.

Freaking unreal project awesome job man

Thanks @ganjafarmer! The friend that gave me the panel routinely visits a scrap yard that has solar panels at it and they will get me more of them if I can successfully repair them. The polyurethane was about 18 dollars USD and the plastic putty knife was like 3 dollars USD and the panel was 13 dollars USD so basically minus labor and transportation I have a working 325 watt panel for 34 dollars USD which would make it (if my math is correct) a total cost of 9.5 cents a watt. :)

@jacobpeacock Great pictures and explanation on how to repair a solar panel

Thanks @myjob!

This post was shared in the Curation Collective Discord community for curators, and upvoted and resteemed by the @c-squared community account after manual review.

@c-squared runs a community witness. Please consider using one of your witness votes on us here

Thanks @c-squared!

This is a very helpful post brother! My buddy damaged some panels moving them on his property. I just sent this article his way so he can look to repair the damaged ones and put them in service. You're the man @jacobpeacock!

Posted using Partiko Android

Glad you find it helpful @makinstuff! I was really surprised when I learned how to do it that it was not more 'common knowledge'. You would think that the DIY crowd would be all over buying solar panels at scrap metal prices and repairing them. The polyurethane cost eighteen dollars USD and the 325 watt panel cost thirteen dollars USD from the scrap metal yard!

One thing that may be worth mentioning to your friend is that it is a good idea to also check the 'short circuit voltage' on the panels. It is actually an amp reading but I did not want to include it in the article because it would seem confusing. I am still unsure if the 'short circuit voltage' rating (9.25 amps in my case) is the reading that I am supposed to see if the panel has a short circuit. I did numerous searches online and could not find an answer so I left it out of the article.

Hello..:-)

@jacobpeacock

Cool..!!!!!

I have one panel that is undamaged and was going to just keep that one and toss the the broken one... But I'm definitely rethinking that now..!!!

Do it @annephilbrick! In your extreme weather scenario be sure to use either a quality outdoor polyurethane or an epoxy so that it will last and you won't need to redo it periodically.