challenges and strategies of Tunnel Construction

Challenges and strategies for tunneling construction

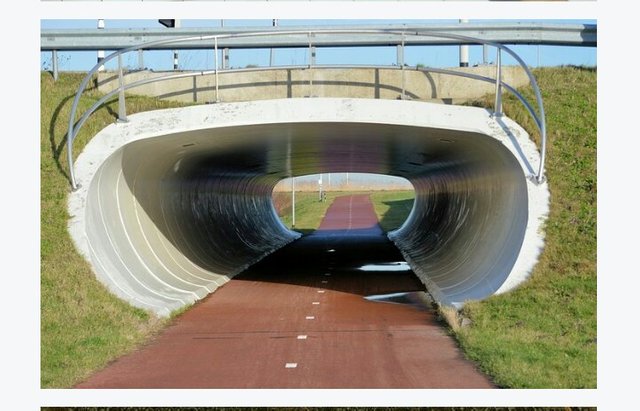

Tunnel construction is an underground passage way provided beneath the surface of the earth or water, tunnel construction is expensive but yet saves time and it’s efficient. In tunneling construction large excavation of soil or rock are dogged etc. in tunnel construction, with the availability of well-equipped instrument such as TBM (tunneling boring machines), excavation and backfilling has become easier. Tunnels can be used for railways, roads and even as waterways in many cities.

Tunnels are key elements of a nation’s development or infrastructure. Mostly invisible and out of sight, they play a key function in urban transportation, sewerage and water transportation, and in hydro-electric power and many other sectors.

However, even with the efficiency and time it’s also a very risky project to undergo, tunneling comes with a lot of challenges and in tunnel construction it’s a project which needs accuracy and proper alignment from surveyor’s, civil engineers and other expertise. bIn order to avoid the collapse of tunnels or shafts. in October 2017 something tragic happened in north Korea where about 100 workers where working in a mine shaft and at that process the shaft collapsed and then another set of 100 workers tried to rescue those inside when the other shaft collapsed so you see tunneling is a very risky job but yet if all the rules and measures that guide tunneling are put in place it will help so much in the management of risk.

Methods of tunnel construction

There are several methods used in tunnel construction such as:

o Cut and cover method

o Bored tunnel method

o Shaft method

o Clay kicking method

o Pipe jacking method

o Box jacking method

o Underwater tunnel

Cut and cover method: In cut and cover method it can be done by two methods. 1. Bottom up method in which a tunnel is excavated under the surface using ground support.

- top-down method in which side support walls are constructed first by slurry walling method or contiguous bored piling Most of the underground metro rail stations are constructed using this method.

Bored tunnel method: bored tunnel method deals with the use of a tunnel boring machine which has an acronym such as TBM, The TBM makes the entire tunneling process easier. It is also a quicker process and good method to build tunnel in high traffic areas. The only difficulty with this TBM is its weight, difficulty in transportation and very expensive.

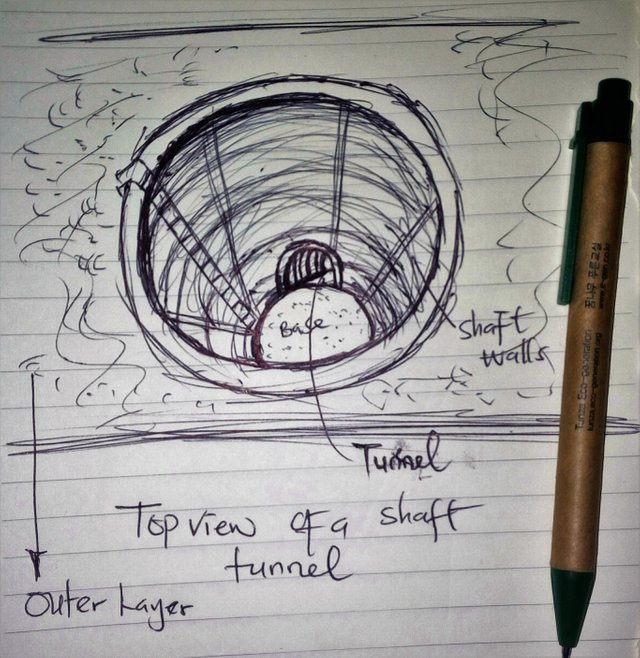

Shaft method: shaft is a permanent structure dogged to a considerable depth where construction of a tunnel is to take place. After construction this shaft can be used as an emergency route for exit or also as a source of ventilation to a tunnel.

My sketch of what a shaft looks like

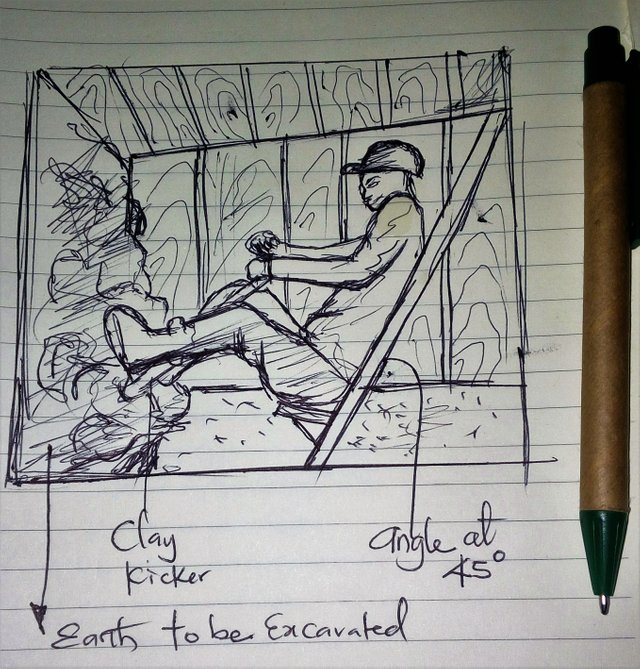

Clay kicking method: This is an old method and used for small, in this method, a hole is excavated into the ground and after some depth tunnel is excavated which is done by the clay kicker which lies on a plank at 450 angle.

This is well-known because it is the method used by Englishmen to put mines under the German empire during First World War.

this my sketch shows how tunnel is being dogged during tunnel construction as regards to clay kicking method

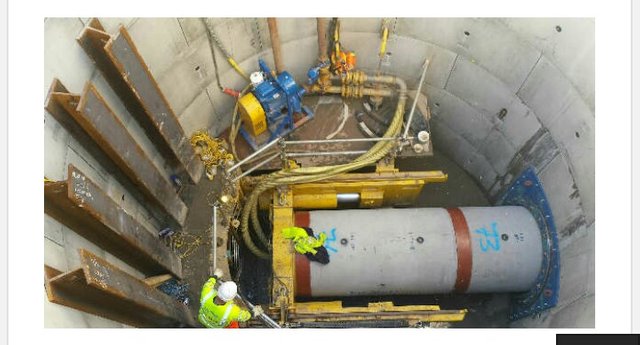

Pipe jack method: Pipe jacking method is used to construct tunnels under prevailing structures like road ways, railways etc. in this method, specially made pipes are driven into underground using hydraulic jacks. Maximum size of 3.2-meter diameter is allowed for tunnels.

Box jack method: Box jacking method is comparable to pipe jacking, but in this circumstance instead of pipes, boxes are made specially and are driven into the soil. A cutting head is provided at the front side of the box. Excavated material are collected within the box.

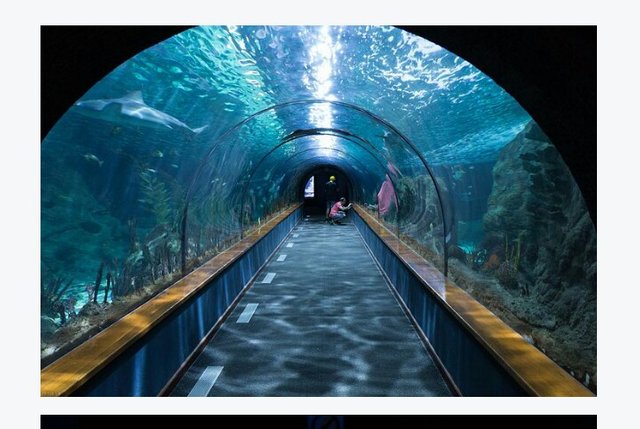

Under water tunnel: under water tunnel this are tunnel done under water, if construction of bridge is not possible then

under water tunnel is a good choice aside that under water tunnel is very expensive to construct but it also helps to reduce noise pollution.

There are certain factors to consider when doing tunnel construction

- Determine the purpose of the tunnel it is often said that “when a purpose of a thing is not known abuse is inevitable”.

- Determine the part in which the tunnel would follow

- Determine where the tunnel would be built

Challenges of tunnel construction

There are several challenges which occurs during tunnel construction such as - Ground behavior

- Existing condition

- Groundwater and Water Flow

- Compressed air

- Rock face fallout

Ground behavior: Ground behavior refers to the behavioral nature of the ground when construction has started. The ground –the rock or soil –behaving differently than excepted is the most significant problem involved in tunnel construction. The nature and configuration of the ground has inferences for how construction should be approached; with hand-mining, drill-and-blast, with shield or with tunnel-boring machines. Additionally, the presence of water can affect ground behavior.

Existing condition: existing conditions is a key challenge in tunnel construction which is a very sensitive part in the process of tunnel construction, Engineers should take care to know as much as possible about surface and underground structures, as well as possible dangerous materials stored in the ground.

Sometimes construction can expose gases. These gases can be poisonous and can cause construction problems.

Ground and water flow: The occurrence and movement of water can impact ground behaviour, which pose a risks to tunnel construction. Flowing water might carry materials into freshly dug openings, causing a form of instability in the mass of rock. Moreover, water can change the ground’s behaviour, making it unpredictable.

Compressed Air:

Compressed-air techniques of tunnel construction are used mainly on earth tunnels through water-bearing soils or adjacent to bodies of water. This technique is the most reliable technique of tunnel construction when the tunnel is being built below the water table, particularly when face instability and water flow are foreseen to be acute.

Rock face fall out: Rock face fall-out refers to when rocks fall from the construction face as a result of weakening ground and support conditions. According to studies, most accidents because of rock fall happen when workers approach a tunnel, cutting face in order to mount a steel arch support.

In order to prevent rock face fall-out, the technique of “concreting” is used. Concreting refers to spraying a newly excavated surface with a coat of concrete in order to give temporary support to the newly exposed rock face. It also helps stop ground surface deterioration and secures loose materials. If done remotely, this greatly reduces the dangers of rock face fall-out.

STRATEGIES FOR HANDLING THE CHALLENGES OF FAST TRACK TUNNELLING

Adequate Geological & Geotechnical Investigation: It is fundamental to have a good assessment of geological conditions before hand to augment the construction activities. A detailed topographic survey would be required to finalize the alignment of the tunnel and location. Locations of significant features such as streams, visible fault zones etc. need to be recognized. For tunnels of long lengths or going through a large spread of land, faster methods of survey than the traditional Total Station-based surveys would be resorted to. The modern tools of surveys such as Aerial surveys, photo-grammetry-based surveys, and GPS based systems.

Drifting: drifting is sometimes very difficult to locate fault zones or share zones or other significant features which have a large impact on the tunnel construction. Though bore whole data, the traditional method of geological exploration provides useful information, it may not be sufficient for overall assessment of the geological features along the tunnel alignment. Exploration by drifting.

Financing: financing has to do with monetary aspect for projects of construction, it is significant that financial arrangement be effected before beginning of the actual construction to ensure that proper cash flows are available at all times throughout the construction.

Construction Agencies Construction Industry. Keeping in view the execution of large no. of projects for accelerated development of tunnel projects, sufficient agencies are not available in the country. To enable more construction agencies to enter in the field, Policies and procedures have been simplified by Govt. of India. With the change in policy and procedures, some international reputed companies have already started operation in India in recent past.

Site Clearances: In some projects, bids are invited before obtaining the statutory clearances. Even the Letter of Award of works is issued combining the completion period say 45 - 60 months stating that the period of completion starts from the day of receipt of the letter of award by the contractor. In such situations contractual problems arise resulting in delay and cost over-runs. Efforts be made to ensure the statutory clearances are available before awarding of works.

Adequate Contracting Practice: Keeping in view the delay and cost over runs being caused, the developers and also the Government should take the lessons from their previous experiences and prepare a Model Contract Document consisting of following to be used as guidelines for adoption in future projects. (a) Standard Bidding Document Guidelines. (b) Works Manual Guidelines (c) Arbitration Manual Guidelines (d) Schedule of Rates and Construction Cost Indices Guidelines (e) Guidelines for grading of construction agencies.

CONCLUSION

Tunnels are generally situated in difficult environments in rocks of various types’ hard or soft and the alignment could pass through various complexities. It is significant that such engineering projects are properly conceptualized and systematic to ensure smooth implementation. It is also to be ensured that adequate investigations have been carried out, proper selection of tunnelling equipment has been made, and appropriate contracting practices are availably taken care of.

REFERENCES

Ahuja, H.N., Nandakumar, V. 1985. Simulation model to forecast project completion

time. Journal of Construction Engineering and Management, ASCE, 111 (4). Pp 325-342.

J.P.Dudt (1999). Risk assessment for tunnel construction cost and time. Proceedings UN/ITA WORKSHOP Costing of TBM built Tunnels Rabat,22-24 April’1999

Keep it up bro!

Thanks buddie