THE ROLE OF STARTER CULTURE IN BEER PRODUCTION AND SPOILAGE

source:zdnet3.cbsistatic.com

source:zdnet3.cbsistatic.com

Starter cultures are preparations of living microorganisms that undergo certain metabolic activities which have desired effects in the fermentation of the food(Brandt, 2014). Started culture is required in producing fermented foods (Hansen, 2014). Some foods in which starter cultures play a role include yogurt, beer, wine, fruits, vegetables milk, meat and cereals(Bamforth, 2008). Basically, starter culture may contain bacteria, yeast, and molds (Miracle et al, 2005).

The preparation of starter cultures may contain unavoidable residues from the substrate and other additives that support the vitality and technological functionality of the microbes (Vogel et al, 2011; Stevens et al, 2009) such as antifreeze and antioxidant compounds as indicated by Brandt(2014)

There are two starter cultures (Hansen, 2014) depending on the number of different species of microorganisms involved (Vogel et al, 2011). The types are a single culture or the wild culture according to Vogel and others (2011). Single culture involved the use of a particular strain of yeast or bacterium for the induction of the fermentation needed in (Miracle et al, 2005). For example, the use of Saccharomyces cerevisiae for the production of alcohol in beer production will be termed as a single culture since only one strain of Saccharomyces is being used. On the other hand, is the wild culture which involves more than one microorganism in the fermentation process as stated by Hammer (1990).

Starter cultures may be beneficial as well as detrimental to food production (Hammes, 1990) depending on how and when they become involved in the production process (Vogel et al, 2011). The notable benefits are affecting yield efficiency (Hammer, 1990), reducing hygienic risks (Hansen, 2014) as well as contributing to the aroma or flavor of the food (Brandt, 2014).

The flavor profiles of most fermented foods can principally be attributed to the biochemical activities during fermentation (Zannini et al, 2012) in which sugars are converted to ethanol and volatile compounds such as higher alcohols and esters (Vogel et al, 2011). Ethanol and CO2 are the primary by-products formed during fermentation (Mirbach et al, 2005); other yeast compounds that contribute aroma include carbonyls (aldehydes/ketones), higher alcohols, esters, vicinal diketones, fatty and organic acids and sulfur compounds (Vogel et al, 2011). The aroma is added to food as these compounds are produced (Hammes, 1990).

Again, start cultures are able to reduce risks by pathogenic or toxigenic microorganisms (Ammor et al, 2007). Starter cultures may compete with pathogenic microorganisms for nutrients and binding sites on the substrate as noted by Vogel and others (2011). They may show competitive exclusion through better adaptation to oxygen content (Haperkan, 2013). There can also be the formation of antagonistically active substances that can inhibit the growth of pathogenic microbes (Hansen, 2014); an example is the production of lactobacilli organic acids (Vogel et al, 2011).

source:pucha.kz

source:pucha.kz

BEER

The exact origin of beer is unknown even though it has been known to exist in the 18th century B. C.(Alcázar et al, 2012). Beer may have have been important because it provided an alternative to drinking contaminated water or because it serves as a useful product gotten out of wet grains which would have spoilt otherwise. Barley, wheat, corn, rice can all be used to produce beer(Sarlin et al, 2007). However, the classification of beer is dependent on the type of microbe involved in production.

Beer is one of the products which are gotten through fermentation (Mirbach et al, 2015). The fermentation is as the results of the activities of the microorganism present which goes the long run to determine the type of beer being produced. In view of this, starter cultures become very necessary in the production of beer(Brandt, 2014).

source:www.usahops.org

source:www.usahops.org

METHODS OF BEER PRODUCTION

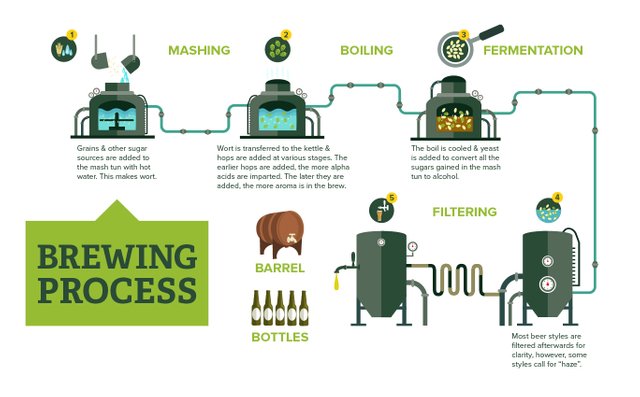

Beer production encompasses five main stages: malting, the germination of barley grains; mashing, a stepwise heating process to promote starch hydrolysis; wort boiling with hops; fermentation; and post-fermentation treatments. Brief description of each stage is given below.

Mashing. While the grain is being mashed, the temperature is raised in steps, each of which optimizes the activity of a different hydroplane. At 52°C, the protein hydrolases are activated. Then at 68°C, the starch hydrolases convert long-chain sugars to the disaccharide maltose, which can support yeast fermentation. The final temperature (77°C) inactivates all enzymes; then the mash is cooled, pressed, and filtered. The liquid filtrate of the mash is called wort.

Wort boiling The wort is inoculated with a special strain of Saccharomyces cerevisiae known as brewer’s yeast. The yeast conducts ethanolic fermentation on the maltose from hydrolyzed starch. At the same time, minor by-products, such as long-chain alcohols, impart good flavors.

Fermentation. The wort is inoculated with a special strain of Saccharomyces cerevisiae known as brewer’s yeast. The yeast conducts ethanolic fermentation on the maltose from hydrolyzed starch. Simultaneously, by-products that are minor can impart good flavors. The time of fermentation is a key factor in the quality of the beer.

Post fermentation treatment. This step includes filtering of the wort to remove the bulk of the yeast. The product, now recognizably beer, still contains undesirable levels of acetaldehyde and diacetyl generated by partial oxidation. These oxidized by-products can be reduced by the few remaining yeast cells during a period of secondary fermentation.

source:images.ctfassets.net

source:images.ctfassets.net

ROLE OF STARTER CULTURES IN BEER PRODUCTION

There are two main types of fermentation used: the Wild and the Single-Culture. A Single-culture refers to a sole strain of yeast that is introduced to consume the sugars in the wort, turning them to alcohol. On the other hand, beers that are sour experience wild fermentation; this means several yeast types and bacteria cooperate symbiotically to convert the sugar into alcohol. Beers can sometimes be also subjected to either a controlled or an open-air fermentation. Controlled fermentation involves the utilization of multiple types of bacteria as well as yeast. The various starter cultures other than Saccharomyces that may be inoculated into the wort are listed below including their functions:

Brettanomyces: A strain of yeast which serves the same function as Saccharomyces does, fermenting beer. However, Brettanomyces does not work very fast. This means the beer which could have been amply fermented within few days or few weeks with a Saccharomyces strain will rather take several long weeks, months, or even years to reach its full potential when Brettanomyces is utilized.

Lactobacillus: A bacteria, not a yeast. Lactobacillus eats up the sugars in the wort and, rather than converting them to alcohol, converts them to lactic acid. This lowers the liquid’s pH, making it sour. These types of cultures do not necessarily top up an appreciable amount of alcohol in the beer, rather they chiefly contribute to the aroma of the finished beer

Pediococcus: A bacteria, not a yeast. Just like a Lactococcus, a Pediococcus can produce lactic acid which can lower pH. Nonetheless, all things being equal, the resulting sourness from the introduction of pediococcus is “harsher” than that of lactobacillus. While Lactobacillus produces a clean sourness, pediococcus can contribute other funky aromas and flavors to the mix.

SPOILAGE OF BEER

Beer includes microbial activity at each stage, from raw material production and malting to steadiness in the package. The vast majority of these activities are alluring, as beer is the consequence of customary food fermentation, but others represent threats to the quality of the final product and must be controlled effectively through cautious administration.

Lactic acid bacteria are divided into two categories based on their by-products of fermentation. The homofermentative group produces primarily lactic acid whereas hetero fermentation group produces lactic acid, acetic acid, ethanol, and carbon dioxide. Either group may cause spoilage in beer when the bacteria byproducts are not desired. Lactobacillus and pediococcus are the homofermentative bacteria known mostly for causing beer spoilage. Off-tastes and smells are created frequently by wild yeast and lactic acid microorganisms ( Lactobacillus and Pediococcus).

Bacteria are able to produce dimethyl sulfide, diacetyl, cis-3-hexanal and organic acids which can contaminate beer. Some yeast strains produce acetaldehyde which gives a rotten apple taste to the beer.

ROLE OF STARTER CULTURES IN BEER SPOILAGE

Gram-positive bacteria

• Lactobacillus: known to produce extracellular polysaccharides causing 'rope' in beer. Notable among them is Lactobacillus pastorianus

• Pediococcus: known to be associated with "sarcina sickness" in beer, characterized by turbidity, acidity, and diacetyl. Notable among them is the Pediococcus damnosus

Gram-negative bacteria

• Acetic acid bacteria: known to cause spoilage of veers stored in the presence of air. Notable among them is the Gluconobacter oxydans.

• Zymomonas: known to grow readily in beer producing turbidity and serious off-flavors. Notable is the Zymomonas mobilis

• Enterobacteriaceae: grow rapidly in the wort, producing metabolites that can affect beer flavor adversely. An example is Hafnia alvei.

Yeast

• Saccharomyces: may produce unintended fermentation, producing turbidity and off-flavors. Examples include Saccharomyces cerevisiae and Saccharomyces bayanus

• Brettanomyces: may produce large quantities of acid that can seriously affect the flavor profile of a beer. Notable includes Brettanomyces lambicus

REFERENCE

*Alcázar, Á., Jurado, J. M., Palacios-Morillo, A., de Pablos, F., & Martín, M. J. (2012). Recognition of the geographical origin of beer based on support vector machines applied to chemical descriptors. Food Control, 23(1), 258-262.

Ammor, M. S., & Mayo, B. (2007). Selection criteria for lactic acid bacteria to be used as functional starter cultures in dry sausage production: An update. Meat science, 76(1), 138-146.

Brandt, M. J. (2014). Starter cultures for cereal based foods. Food microbiology, 37, 41-43

Hansen, E. B. (2014). Starter Cultures: Uses in the Food Industry. In Encyclopedia of Food Microbiology (pp. 529-534). Elsevier Science.

Hammes, W. P. (1990). Bacterial starter cultures in food production. Food Biotechnology, 4(1), 383-397.

Mirbach, M. J., & El Ali, B. (2005). Industrial Fermentation (Chapter 9). Handbook of Industrial Chemistry. Organic Chemicals. New York: Mc Graw-Hill.

Vogel, R. F., Hammes, W. P., Habermeyer, M., Engel, K. H., Knorr, D., & Eisenbrand, G. (2011). Microbial food cultures–opinion of the Senate Commission on Food Safety (SKLM) of the German Research Foundation (DFG). Molecular nutrition & food research, 55(4), 654-662.

Heperkan, D. (2013). Microbiota of table olive fermentations and criteria of selection for their use as starters. Frontiers in microbiology, 4, 143.

Bamforth, C. W. (2008). Food, fermentation and micro-organisms. John Wiley & Sons.

Sarlin, T., Vilpola, A., Kotaviita, E., Olkku, J., & Haikara, A. (2007). Fungal hydrophobins in the barley‐to‐beer chain. Journal of the Institute of Brewing, 113(2), 147-153.

Stevens, H. C., & Nabors, L. O. (2009). Microbial food cultures: a regulatory update. Food Technology (Chicago), 63(3), 36-41.

Zannini, E., Pontonio, E., Waters, D. M., & Arendt, E. K. (2012). Applications of microbial fermentations for production of gluten-free products and perspectives. Applied microbiology and biotechnology, 93(2), 473-485.

wow. This looks as though it is something you could have submitted for professional peer review. I have to admit I did not read all of it but it is very thorough.

Was this a school project? It certainly reads like one.

Naa... it wasn't a project.