Preparation of agricultural inputs through the technique of biodigestion

Dear friends, followers and members! of the Steem platform.

Serve the opportunity, to share with the entire academic community of the social network Steemit, scientific and technical information on ELABORATION OF LIQUID AGRICULTURAL SUPPLIES, this time on the method of production by biodigestion.

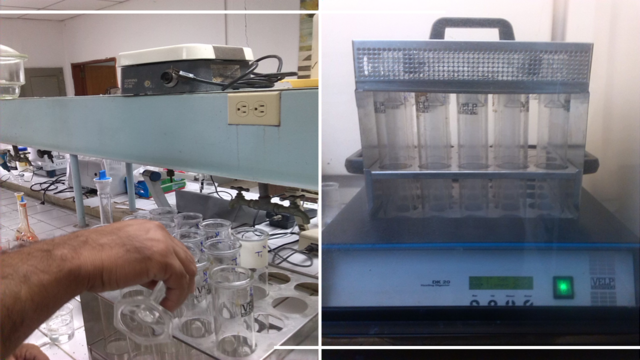

Fig. 1 Elaboration of liquid agricultural supplies. Author: @lupafilotaxia.

Introduction

To liquid organic fertilizers, it is also often referred to as liquid biofertilizers or bioles, conceptually they are Bio-products that are originated by the metabolic action exerted by anaerobic microorganisms, on the decomposition of organic materials of animal and vegetable origin, in closed containers called biodigestores, the liquid biofertilizers as they are generally called, contain considerable concentrations of macro and micronutrients, phytoregulators and other metabolites with specific bioactivity, which when applied in cultivated species promote certain physiological activities, stimulating with it the vegetative growth, development and fructification [7].

It should be noted that the liquid biofertilizers made in biodigesters, are widely processed in an artisanal way, this non-industrialized aspect in addition to reducing production costs, does not pollute the ecosystems achieving this, increase crop production bioeficiently and simultaneously give it a reuse to organic waste, which many times what they do is to contaminate the soil and fresh water destined for human consumption, it is for this reason and based on these considerations, that the objective of this post is to describe the production technique through biodigestion and the methods used for the determination of the main physical-chemical quality indicators of these Bio-liquid products.

Liquid biofertilizers

Use in agricultura

These Bio-products in liquid presentation, function as growth promoters in the cultivated plants, thanks to the presence of plant hormones (adenines, purines, auxins, gibberellins and cytokinins) that come from the metabolic reactions induced by the bacteria that act in the anaerobic fermentation of the process, highly beneficial situation that allows to reduce the use of chemical fertilizers widely used in agricultural activities to stimulate vegetative production in crops [3].

| Indoacetic acid | |

| Gibberellins | |

| Purines | |

| Thiamines (B1) | |

| Riboflavin (B2) | |

| Pyridoxine (B6) | |

| Pantothenic acid | |

| Cyanocobalamin (B12) | |

| Tryptophan |

Another favorable aspect of liquid biofertilizers in agriculture is that these bio-products can be applied in increasing doses or in concentrated form (pure state), the most widely used method of application is by spraying directly on the foliage of crops , well from; short cycles, annual, biennial, perennial, grasses, forage species, legumes, fruit trees, vegetables, roots, tubers or ornamental plants [1].

Among the main advantages, which exhibit liquid biofertilizers in agriculture are:

➊ They allow a better cation exchange in the soil, increasing the availability of nutrients.

➋ They help maintain soil moisture and create a suitable microclimate for plants, promote physiological activities.

➌ They stimulate the development of the plants when acting on the rooting, emission of foliage, active flowering and germinative power in the seeds.

➍ Increase resistance to pests and diseases.

➎ They maintain balanced values of N, P, K, Ca, due to the anaerobic decomposition process which allows us to take full advantage of the nutrients.

➏ They have nitrogen in an ammoniacal form easily assimilated by the crops.

Soil factor

The liquid biofertilizers, play an important role in the recovery of soil fertility, not only by the contribution of mineral elements such as nitrogen, phosphorus, potassium, calcium and magnesium, but also, by the addition of beneficial microorganisms that improve the soil biota, on the other hand, agricultural producers have been using liquid biofertilizers more frequently, as a replacement to conventional (synthetic) fertilizers, this is due to the stimulating effect of liquid organic fertilizers on the growth of plants through the synthesis of substances that strengthen the nutritional balance, it is also important to highlight that in field tests carried out in different countries, it has been shown that these bio-products activate defense mechanisms in plants, making crops less prone to attack of pests and diseases.

| Total solids | |

| Organic material | |

| Fiber | |

| Nitrogen | |

| Phosphorus | |

| Potassium | |

| Calcium | |

| Sulfur | |

| Ammoniacal nitrogen |

Techniques and methods of elaboration

Biodigestion

Liquid biofertilizers can be made using the anaerobic biodigestion technique, this procedure consists of adding the organic waste in a container with lid (biodigester), which allows to make a hermetic seal, to the lid an opening is opened in the central part and a tube of approximately 50 cm long is placed in order to expel the gases generated during the fermentation process, it must be connected to a container with water, the fermentation time ranges between 20 and 30 days and it will depend on the materials added [5].

Fig. 2 Plastic bio-digester with a capacity of 200 liters. Author: @lupafilotaxia.

Operation of the biodigester

For the correct functioning of the biodigester, the quality of the raw material or biomass must be guaranteed, the digestion temperature must be maintained between 25 and 35 ° C, pH around 7.0 and the hermetic closed conditions of the biodigester, all this , to create the ideal conditions in each one of the anaerobic activities of the process, in the same way, it is important to consider the ratio of dry matter and water, which implies the degree of particles in the solution, it is recommended that the amount of water, I placed around 90% by weight of the total content, both the excess and the lack of water are harmful, on the other hand it is important to mention that the amount of water varies according to the raw material destined to fermentation [7].

Anaerobic microorganisms

The anaerobic microorganisms that sequentially intervene in the process are: hydrolytic and fermenting bacteria, forced acetonogenic bacteria reducing hydrogen protons, hydrogen sulfate-reducing reducing bacteria, homoacetogenic bacteria, methanogenic bacteria and denitrifying bacteria.

Bio-production method

Organic materials of animal and vegetable origin must be added to the biodigester, either in plastic drums of 200 liters capacity or higher capacity tanks constructed of cement or metal, according to [7], the ideal proportion of materials must respond to the following formulation; 40 kilograms of cow dung or chicken manure, 10 kilograms of fresh vegetable biomass, 1 kilogram of ash, 1 liter of molasses, 1 liter of milk, these materials must be mixed in water to complete the 200 liters, the addition of yeast or other is recommended microorganisms that can accelerate the process, once the process of biodigestion of the mixture is completed, the resulting liquid biofertilizer is extracted through the use of sieves, separating with it the solid materials that failed to degrade in the bio-process.

| Manure | |

| Vegetable Material | |

| Ash | |

| Molasses | |

| Milk |

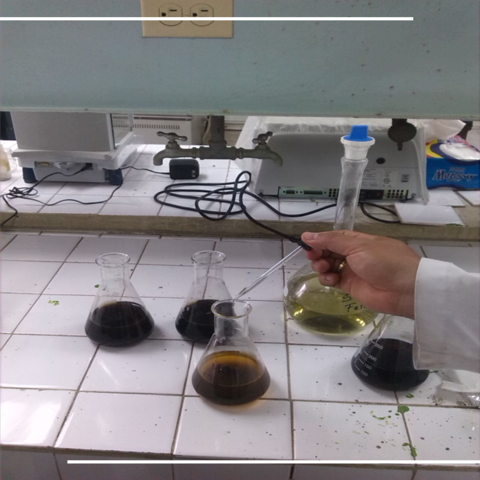

Fig. 3 Mixture of energy sources used in the preparation of liquid biofertilizer. Author: @lupafilotaxia.

Physical-chemical determinations

In this segment of the post, the main analysis techniques used for the physico-chemical determinations of liquid biofertilizers will be described in detail, in this sense, experimental procedures performed in the Chemical Analysis Laboratory, located at the National Experimental University, will be socialized. South of the Lake (LAQUNESUR), municipality of Colón, Santa Bárbara, Zulia state - Venezuela, the following methods being outlined:

Total nitrogen / Kjeldahl method

To determine the total nitrogen of the liquid biofertilizers, the method of digestion and distillation using Kjeldahl was used, for this they were used; DK-20 digester, PRO-NITRO S distillation equipment, burettes, precipitated beakers, heating plate, Kjeldahl tubes and reagents (boric acid, sulfuric acid, ethanol, copper sulfate, methyl red).

The procedure consisted of digesting the bio-products in high temperatures and in acidic conditions, using copper sulphate as a catalyst, this with the purpose of converting the organic nitrogenous elements to ammoniacal compounds [2].

Fig. 4 VELP Scientifica Team DK-20 for digestions. Author: @lupafilotaxia.

Once the digested samples were obtained and when the Kjeldahl tubes were at room temperature, they were taken to the distillation system there once the process was completed, proceeded to the ammoniacal determination.

Fig. 5 Distillation equipment PRO-NITRO S. Author: @lupafilotaxia.

pH / direct reading method

The pH of the liquid biofertilizers was determined by direct reading through the use of portable pH meter of multiple work, Brand: OKATON, under a ratio of 1: 5 for the samples of liquid biofertilizers [8].

According to the direct reading method, before starting the measurements, the equipment must be calibrated with Buffer solutions (pH standards 4, 7 and 10), then place the sample, introduce the electrode and finally take the reading of the constant value.

Fig. 6 pH meter / mV / ° C meter 9033 Multi-range. Author: @lupafilotaxia.

Electrical conductivity / direct reading method

The electrical conductivity (C.E) of the liquid biofertilizers was determined by direct reading through the use of a HI 9033 Multi-range conductivity meter [6].

The technique of measuring the electrical conductivity in liquid biofertilizers consisted of introducing the conductivity meter into the liquid samples, obtaining the fixed readings expressed in mS / cm.

Fig. 7 C.E./ HI 9033 Multi-range meter. Author: @lupafilotaxia.

Phosphates / colorimetric method

The evaluation of the phosphates present in the liquid biofertilizers was determined using the colorimetric method using the standard method of ascorbic acid, the absorbance of each sample was measured in a spectrophotometer [8].

Fig. 8 Procedure to determine Phosphates, phenolphthalein drops are added to the liquid biofertilizer samples in the image. Author: @lupafilotaxia.

SCIENTIFIC CONTRIBUTIONS OF THIS PUBLICATION

- In this post, the scientific contributions focused on socializing technical procedures for the production of liquid biofertilizers through the biodigestion method, whose means of production is highly accepted and used in agroecological agriculture, due to the characteristics of mineral and microbiological quality exhibited by the Bio-final products, and at the same time present procedures at the laboratory level in order to guide from the scientific point of view, the methods used to make the determinations of the main indicators of physical-chemical quality of liquid biofertilizers.

BIBLIOGRAPHICAL REFERENCES CONSULTED AND CITED:

[1] Bejarano C., Méndez H., nd Gordillo E. Organic Fertilization compared to Chemical Fertilization in the Bean Growing (Phaseolus vulgaris), to minimize the effect of Soil Degradation. Undergraduate thesis. North Technical University. Faculty of Engineering in Agricultural and Environmental Sciences. Province of Ibarra, Ecuador. 2004;128.

[2] Cope W. Kjeldahl modification for determination of nitrogen in nitro substitution compounds. J. Ind. Eng. Chem. 1916; 8:592-593.

[3] Galindo A. ; Jerónimo C., Spaans E. and Weil M. Fermented liquid fertilizers and their effectiveness in papaya seedlings (Carica papaya L.). Magazine of the EARTH University. 2007;3:1:91-96.

[4] Hayes T., Jewell W., Orto D., Franconi K., Genschener A., and Sherman D. Anaerobic digestion of cattle manure. pp. 255-286. In: A. Stafford, B.I. Wheatley y D.E. Hughes. Anaerobic digestion. Applied Science Publishers. London, England. 1979.

[5] Kennedy J., and Berg D. Anaerobic digestion of piggery waste using a stationary fixed film reactor. Agric. Wastes. 1982;4:151-158.

[6] Rhoades J. Salinity: Electrical conductivity and total dissolved solids. p. 417-435. In J. M. Bartels et al. (ed.) Methods of Soil Analysis: Part 3. Chemical Methods 3rd. ed. ASA and SSSA, Madison, WI. Book series no. 5. 1996.

[7] Ricardo S. Study of the production of small scale bioles from three manures and their possible agricultural use. TG - UNESUR. 2013;98.

[8] TMECC. Test Methods for the Examination of Composting and Compost.2002.

✔ The videos and photos are the property of the author @lupafilotaxia, and were taken with a digital camera Model Samsung HD 5X Touch Screen.

✔ All the designs of images and graphic figures were made by the author @lupafilotaxia, through the Office Power Point 2017 program.

ATTENTION / Readers and Followers

If you want to read more scientific articles of excellent academic quality, do not waste time, and visit the label #steemSTEM, is a large community that values and promotes scientific content, mainly in the areas of Science, Technology, Engineering and Mathematics.

INVITATION

Dear reader, if you wish to obtain more information about it, join our server in Discord

OBSERVATIONS

✔ The POST 📧📨 was uploaded using the official app of https://www.steemstem.io

OBSERVATIONS

✔ The POST 📧📨 was uploaded using the official app of https://www.steemstem.io

You can visit the official app of our community

https://www.steemstem.io

This post has been voted on by the SteemSTEM curation team and voting trail. It is elligible for support from @curie and @utopian-io.

If you appreciate the work we are doing, then consider supporting our witness stem.witness. Additional witness support to the curie witness and utopian-io witness would be appreciated as well.

For additional information please join us on the SteemSTEM discord and to get to know the rest of the community!

Thanks for having added @steemstem as a beneficiary to your post. This granted you a stronger support from SteemSTEM.

Thanks for having used the steemstem.io app. You got a stronger support!

Thanks SteemSTEM

Hi @lupafilotaxia!

Your post was upvoted by Utopian.io in cooperation with @steemstem - supporting knowledge, innovation and technological advancement on the Steem Blockchain.

Contribute to Open Source with utopian.io

Learn how to contribute on our website and join the new open source economy.

Want to chat? Join the Utopian Community on Discord https://discord.gg/h52nFrV

Thanks Utopian Community

Any thoughts on whether our soil, historically speaking, is increasingly being depleted of substances, like magnesium for instance, despite efforts to put them back in?

Greetings @alexander.alexis, thanks for visiting the blog.

The loss of soil in natural or artificial ecosystems, is related to the decrease of the organic fraction, therefore, what is really running out is not the mineral substances or elements, but their form of assimilation, or in other words their availability as a source of adsorption. Hence, the importance of complementing the fertilization programs by adding Bio-products with the objective of promoting the biological recovery of the soil.

In the case of Bio-products, rich in Magnesium, it is recommended to apply those that are based on poultry manure, spinach biomass and dry material of fabaceae species.

Best regards.

A learned answer, thanks!