How to make a bottle opener.

Here you can see how I make one of the conical parts of the piece on a lathe; the trolley that is moving is the trolley that is attached to the turret tool holder.

A high-speed steel turning blade was used and the angle with which this cone is being made is 7.12°.

The lathe’s rotational speed is 445 rev/min and the manual linear feedrate is estimated at 0.8 mm/rev.

I am currently studying a subject called manufacturing process 2, in which we are being instructed on machine tools. My final evaluation in the laboratory was the realization of this beautiful bottle opener. I consider it a very interesting experience and I would like to share it with you.

I know that you may think that its’s a simple bottle opener, but I will show you the whole process that is going on.

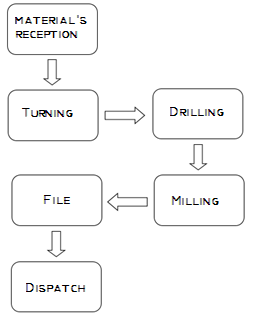

The step by step:

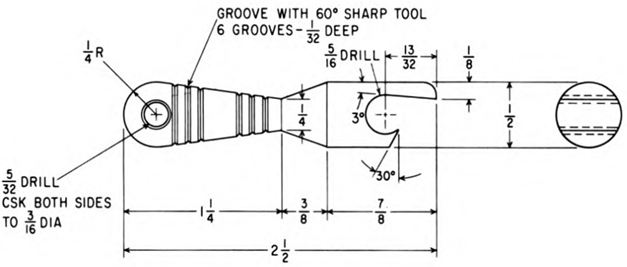

The drawing provided is read and interpreted to identify the dimensions of the part, this process is the most important, since it is possible to define the machinery that is going to be used in the process.

A mental step by step is developed to define the equipment and cutting tools to be used.

Then we proceed to define each process in detail, here I will only explain the processes above, since the calculations are a very long subject to cover, but if you want me to explain them, a single comment will be enough to make a post about the calculations.

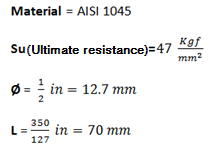

First it is necessary to define the material to be processed :

Then define the operations to be performed:

Operation #1: Assembly on Lathe.

In this operation, the standard AISI 1045 metal cylinder was simply clamped in place with the help of the 3 self-centering jaws of the lathe and the machine was prepared for the start of machining (removal of chips from previous processes, removal of potentially dangerous parts from the surface of the lathe, etc.).

Operation # 2: Facing with the lathe.

The purpose of this operation is to leave one side of the steel cylinder completely flat for subsequent machining. A cutting tool is used for facing or a turning tool can also be used for turning by adjusting the angle of attack.

Operation # 3: Contour turning.

This operation is carried out with the aim of giving a rounding to the newly facing end and thus complying with the design specifications of the capper. Since the radius of the rounding is not specified, a radius of 2mm is assumed. A 2 mm radius contour cutting tool is used.

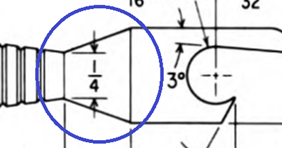

Operation # 4: Tapered turning.

The purpose of this operation is to give the bottle opener the first conical section that is set for its design. From the dimensions shown in the plane and by trigonometry it was concluded that the angle of the conical section with respect to the horizontal is 18.43º.

Operation # 5: Tapered turning.

The purpose of this operation is to give the bottle opener the second conical section within its design. From the dimensions shown in the plane and by trigonometry it was concluded that the angle of this conical section with respect to the horizontal is 7.12º.

These Angles are applied to the jaw that is attached to the turret of the lathe, so the cutting tool describes the same line of the turret.

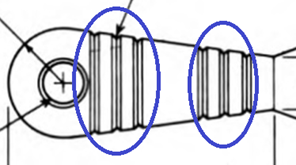

Operation # 6: Slotting (6 slots).

In this particular operation, the 6 grooves are made on the conical section that would have just been machined in the previous operation. As the distance is not specified in the design, the decision taken was to make the first line at a distance of 3 mm from the centre of the circle, and 2 mm apart for the right-hand ones. For those on the left, the neck was taken as a base and a distance of 3 mm was used for the first one and 2 mm of separation between them. All these measures are taken with the angle.

The tool to be used is a 2 mm wide grooving or cutting tool.

Operation # 7: Assembly on the lathe.

The purpose of this operation is to hold the steel cylinder by the part already machined so that the missing end can be machined.

Operation # 8: Cutting.

With this operation we remove the excess cylinder section that is not necessary for the final part. This section was used to hold the cylinder on the lathe in the previous operations, but it is no longer necessary and must be removed in order to complete the machining of the part. The tool to be used is a cutting tool.

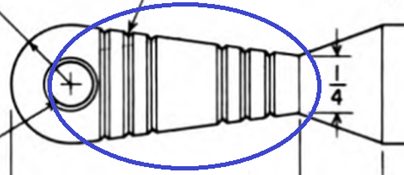

Operation # 9: Contour turning.

This is the last operation on the lathe, which is used to round off the back of the bottle opener. A cutting tool is used with a semi-circular radius cutting edge"¼", and a turning operation is carried out just as it is.

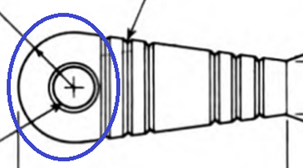

Operation # 10: Mounting on the Bench Drill.

In this operation, the cylinder, which has already been properly turned, is taken to a press to be drilled with 2 small holes with a point center right in the centers of the 2 holes required by the design. This is done to simplify the drilling process and to prevent the drill bit from being twisted by the action of the cylinder geometry.

Also, in this operation, the chuck must be mounted on the drill with the drill bit to be used later.

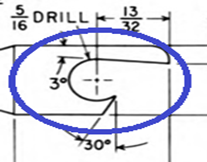

Operation # 11: Drilling (Hole 5/32").

For this operation, a 5/32" diameter drill bit was installed on the drill chuck and a high rotational speed was selected according to previously pre-specified calculations to perform the through-hole drilling.

Operation # 12: Countersinking 5/16".

Without removing the part from the jaw or releasing any brakes, replace the 5/32" drill bit with a 5/36" drill bit and place the previously drilled hole in contact with the new drill bit, then slowly penetrate the hole to achieve the desired diameter of the countersink, the angle of which is described by the drill bit itself.

Operation # 13: Drilling 5/16".

The brakes are released and the drill bit is aligned with the center point previously made. All drill brakes are secured and a low cutting speed is selected due to the diameter of the drill bit, finally, the through hole is drilled.

The angle of attack of the drill bits must be 136° since the part is a steel, this applies to all drilling operations.

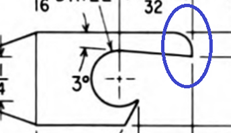

Operation # 14: Milling.

The piece is placed in the clamp of the milling machine and fixed to it with the appropriate angle to make the cut using the goniometer, as it consists of several angles, this operation will be done in several passes.

This time we worked with a cylindrical milling machine, the milling cutter had 8 teeth, with a diameter of 30 mm.

Operation # 15: filing and polishing.

Depending on the depth of the scratches left by the cutting tools, it is necessary to file and then polish with 80 and 120 sandpaper to give them an ideal finish. If you want the piece to be as shiny as mine, you can give it a mirror finish with a 420 sandpaper and a polishing cloth.

And this is the whole procedure to do in the bottle opener, I spent 1 day manufacturing the bottle opener in the laboratory because I had a lack of practice, I hope you like the process.

¿You want to make the same one?

▶️ DTube

▶️ IPFS

Your article is very exciting!

Congratulations @andreacastaneda! You have completed the following achievement on Steemit and have been rewarded with new badge(s) :

Click on the badge to view your Board of Honor.

If you no longer want to receive notifications, reply to this comment with the word

STOPTo support your work, I also upvoted your post!

Congratulations! This post has been upvoted from the communal account, @minnowsupport, by Andrea (andreacastaneda) from the Minnow Support Project. It's a witness project run by aggroed, ausbitbank, teamsteem, someguy123, neoxian, followbtcnews, and netuoso. The goal is to help Steemit grow by supporting Minnows. Please find us at the Peace, Abundance, and Liberty Network (PALnet) Discord Channel. It's a completely public and open space to all members of the Steemit community who voluntarily choose to be there.

If you would like to delegate to the Minnow Support Project you can do so by clicking on the following links: 50SP, 100SP, 250SP, 500SP, 1000SP, 5000SP.

Be sure to leave at least 50SP undelegated on your account.