The daunting task of my basement remodel into a wood shop Post 1

Greetings!

I have finally started cleaning up the corner section of my basement that I will be turning into my wood shop so I can start creating some product ideas I have to make a living.

Since being turned down multiple times for my social security disability claim from my so called government, It was a system I paid into for the last thirty five years or so and they say I’m not eligible because my hands still worked! WTF! Can you believe that? I CAN BARLEY WALK!

Well that leaves me with nothing to do but figuring out what I can do, without standing or moving around for more then five minutes at a time. So I thought about what I liked to do, my hobbies, how could it turn a hobby into a business? I looked at each hobby and looked at how it could potentially become a business.

Raising Honey Bees

Honey bees main crop is honey, a byproduct of creating a hive is wax, a second byproduct of a hive is propolis a glue the bees make from a mixture of honey and wax to seal up air gaps in the hives. Another waste product from a hive is slumgum, it is a product that is left behind after processing and cleaning the wax of impurities. This would be insect bodies of dead bees, hive beetles, ants, etc. So there are three possible incomes streams from a hive as a hobby bee keeper. Other possible incomes are listed below:

Honey

Wax

Propolis (Used in medical applications)

Pollen (used in candies among other things)

Candles (from the wax)

Health Creams (from the wax)

Lip Balm (from the wax)

Metal preservative (a mixture of beeswax and linseed oil is used by blacksmiths to coat their finished products it is also good for coating the workings of gun parts)

wood preservative (furniture polish)

Candies (from the pollen and honey)

Renting out your hives to farmers for pollination of crops (this would be more for a commercial beekeeper but doable if you can manage the logistics of moving hives)

So there are twelve possible income streams from raising bees! Amazing critters they are! They are self sufficient and fast multipliers, All the beekeeper has to do is check the hive twice a week to see if they need more room and see if they need any bee medical help.

Infestation, insecticides poisoning, Colony Collapse disorder, American foul-brood and European foul-brood is a big problem in today's beekeeping.

All this information is available on the internet. The only advise I can give, is before doing anything, research it, read everything you can get your hands on, before you even try to raise bees. After all they are a living community that has a mind of their own. I’ll make a future post just about my experience with raising a colony.

Carpentry

I am by no means a master carpenter. I never claim to be, I hope one day I can be. But we will see what happens. My grandfather is the one that introduced me to carpentry. Later in high school I picked that up as a class “in my day” it was called wood shop. I also took metal shop the same year during a different period. A one hour class consisted of 45 minutes working on a project that each student chose and fifteen minutes going over safety procedures of each machine. Today I have all the basic machines and hand tools to get me started. But like raising bees it can get expensive with up front costs to get your hobby or startup business set up with the proper tooling. For now I have enough to get started. Lets see what products I could make to sell in a carpentry business. List below is just a few.

Boxes

Turned wooden containers with friction fit lids

Furniture (tables, chairs, desks, stools, etc.)

Turned wooden bowls

So there is a lot of potential for creating products out of wood that is only limited by a person’s imagination. Repetition of products is hard for the carpenter for each copy he makes it is going to be ever so slightly different from the last. Differences in materials used, grain patterns of the wood, well you get the idea I’m sure.

Commercial reproduction is more consistent, using up waste products from lumber yards and slapping a vinyl veneer on it for a quick sale. Don’t get me wrong here, commercially produced products serve a purpose in today's society, but that does not mean it produces a better product. That is not an option for a true carpenter in my humble opinion! Each product a carpenter creates by hand is a unique and individual piece of art.

So this is my plan for the next few years. Set up my shop, produce some beautiful keep sake boxes, make templates for later reproduction according to order, Create at minimum ten products in all for website sales, Using the wood shop to create a number of hive bodies that will be used to raise bees.

With these two hobbies I should be able to create a good living for my self and my family without relying on a government that seems to be incapable of protecting our rights and taking everything they can get their hands on.

The Basement

The area available for the wood shop will be 12’x22’ area with 264sq foot floor space, small, but good enough to get started.

Most of the clean up is done and I am in the middle of making my base tables. The two narrow tables on the left will be both up against the wall with the miter saw between them. The big table in the center is going to be an assembly table and out feed table for the table saw. Later it will have a CNC router added to it for making V- carved box lids and carved cabinet doors. The wall above the miter saw and tables will have a french cleat system to hold hand tools and cabinets for finishes, and other accessories. The machines I do not have yet I can purchase as I am able, maybe a manufacturer out there can help me out. Lol.

The amount of light I have seems to be more than adequate for the time being. Later I can maybe get some eight foot defused LED shop lights to replace them. The upper right of the photo there is an area of 11’x12’ with 132sq feet of floor space were the metal shop will be. This should provide enough room to have a small metal lathe, belt grinders, and a mechanics vise to create custom hinges and hasps for my carpentry projects.

If any viewers out there have a craftsmen Apollo 10 or 12 lathe they would like to sell or trade contact me maybe we can work something out that is beneficial for both of us.

Well I think this might be the end of post 1 of the basement remodel for now. Stay Tuned for part 2

If anyone has an idea or questions they would like to see me cover that has to do with carpentry or honey bees leave a comment and I will start a list of topics to cover in future posts.

Peace to all and have a great day!

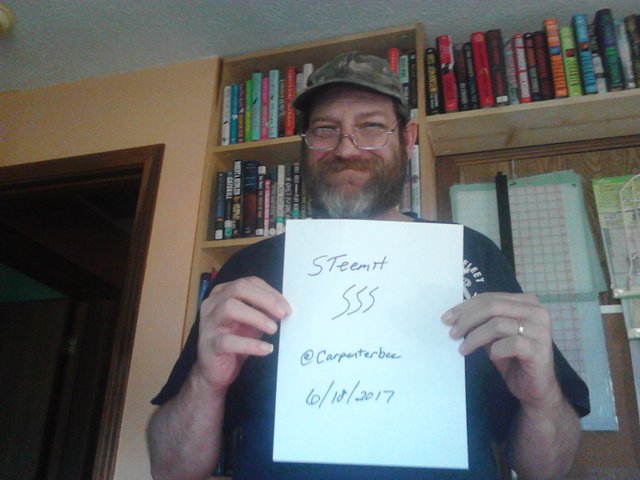

Proof I am the one and only

Cool stuff. I'm a woodworker too. Currently working in a two man shop making mid-century modern stuff out of Detroit. So I have some small familiarity with the high end furniture and art scene. We also just bought a shopbot CNC the other day, we haven't even taken it back to the shop yet. Looking forward to seeing your shop build out.

Ya Followed.

Thank you! I have been thinking about how to set up my shop for quit some time. its a challenge to fit everything in a small space, but for the first year or too I am not planing to build anything to big, other then the cabinets that will hang on the wall above the miter table. I have family in flint! lol Welcome to steemit! It's great to be here!

Really good descriptions! I went through the shop-building a few years ago and it was as much to actually create something and practice building as gaining a shop. I'm glad i took my time because it has been very functional for me.

Will

Yep that's the key! make your shop as functional as can be with as little movement as needed to get the tools you need to do the job. It makes it a comfortable shop when most everything is within a step or two from the work. Thanks for the comment.

I had an uncle who went through the same process and found a way to make it pay off nicely. He got old, weathered barnwood and sawed each piece to thin it and then planed and finished it before staining it. The wood was absolutely beautiful! He joined the smaller pieces and sold it to violin and mandolin builders. Old wood is a great resource!

I indeed agree old wood is beautiful, Just have to smooth it out to see it. This wood is white oak with some very dark streaks in the grain. It is going to look fabulous once it is varnished or shellac, I am not sure which yet. Anytime I see someone ready to burn a pile of wood here that has lengths longer then a foot I try to grab it.

I know the feeling about old wood. There was an 1870s four room home on the perimeter of our land that had been unused for fifty years, and for hay storage before that. ll of a sudden, the owner decided he didn't want it and bulldozed it and burn it to ashes one Saturday afternoon. All that beautiful wood up in smoke! I coulda throttled the guy. I would have cleared it away just for the wood! Ahhh... it comes from a lack of understanding, I guess. I built a set of oak stairs a few years back and have a stack of random pieces of 1" oak that really is not useful but I can't throw it out. Someday, there will be a use for it.