YTM Internship Part-2

I had introduced everyone to Yunus Textile Mills the factory where I had my internship in the Utility department to get a recap visit my earlier post: Internship Part 1

After all the formalities we were inducted in and then began three of the most amazing weeks, during our internship I had learned a lot. The theoretical aspect were already known but here seeing those theories put on a practical scale was just amazing. It was mindboggling to see production on such a huge scale I was feeling quite proud of what the work of an engineer is and how important he is to the industry. It was fun to learn things from very helpful seniors always helping their internees out.

The Utility department had two major productions:

Power Generation:

The factory requirement is about 10-12 MW of electricity daily these requirements are met with powerful engines continuously running to generate electricity, but before we get to the engines firstly a Gas compressor room is laid so that the gas required to burn in the engine furnace is of adequate pressure and concentration. There are two compressors the main purpose of these of these compressors is to increase the pressure of natural gas before entering into the engine. The gas coming into the compressor is about 0.5-1 bar and after it has been compressed the pressure is 5 Bar that is needed for proper operation of the engine.

During my time there was a minute leak on the compressor although I wasn’t allowed near the place because of safety issues but the in charge told me about the process of how to fix the leak. Firstly the room must be properly ventilated and made sure no gas is within the atmosphere because to fix the leak welding is required and there can be an explosion if gas is not properly treated. The welding done isn’t just the normal welding but Argon welding is done because Argon is a noble gas it is very less reactive to the atmosphere.

The Engines

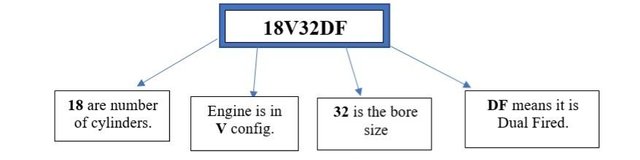

After the gas has been compressed it is transferred through pipes into the engine room this is a huge place where two Wärtsilä engines are kept, there configuration is 18V32DF these are symbols each having a meaning as explained.

The capacities of these engines are 6 MW but are run on 5 MW for a prolonged life and running capacity. Other than this there are 4 MTU engines each producing 3 MW, two are running and two are on standby if in any case a power outage occurs the backup engines are initiated. Within the engine room the sound of the engine is so immense we had to wear protective kits for our ears otherwise the sound may affect our eardrums. The whole experience was amazing the piston bores were as big as a bikes whole engine. For an engine enthusiast that is a big thing. These engines were running without any stoppage for over 4 months straight.

The main feature of the Wärtsilä is that these are HFO convertible meaning they can run on both natural gas and Heavy furnace Oil. The recent Gas shortage in Pakistan had many industries being temporarily shutoff due to very low supple, but YTM was functional because both the engines were operating on the Heavy Furnace Oil.

These engines are monitored through the Control Room where a software known as SCADA monitors the engine exhaust gases and if there is a fluctuation in the pressure level and key features of the exhaust the maintenance engineers are notified immediately.

Steam production

Steam is used in many processes during cotton production operations hence there were many boilers in the facility. Firstly the WHRB Boilers were operating just outside the engine room. WHRB stands for Waste Heat Recovery Boiler, The exhaust gases from the engine have high temperatures and quite a lot of energy which is a real waste to be exhausted into the atmosphere so now these exhaust gases are being utilized to covert water into steam through their heat and energy and hence produce steam. These had fluctuations in the amount of steam produced because this would depend on the exhaust gas coming into the boiler itself.

There were two coal fired boilers also operational, they were called chain grate boilers because the coal being deposited was through buckets run on chains, one had a capacity of 25 tons per hour and the smaller one had a capacity of 15 tons per hour.

Coal fired boilers working is as follows, The coal is burned in a furnace giving high intensity heat and energy on the surrounding, as high temperature gases flow upwards there are tubes placed above the furnace so that when these high temperature gases flow above they convert the water flowing through the tubes into steam there is a water and steam tank above where both water and steam is kept. Water is denser so it is at the bottom and steam is accumulated at the top of the tank. There are pressure gauges and water level indicators to monitor the working of the boiler, the steam is then transmitted through a valve into the respected department which require steam in their processes.

We even had a look inside the furnace when one of the boiler was shut down for maintenance the space was huge within the boiler it was quite dark so we couldn’t get a clear picture but during operation when the furnace door opens it’s like a pit of hell just waiting to burn anything that is thrown in. This was a scary view indeed.

After the duration of my internship I had become a better engineer indeed, to get first-hand knowledge of the operations within an industry is quite satisfying. The amount of work being put into the operations of these huge machines is quite immense. It was a great experience working in Yunus Textile Mills and I would love to come back here as a permanent employ, but till then the journey in Undergrad University continues with the Final Year Project looming large.

Congratulations! This post has been upvoted from the communal account, @minnowsupport, by shaheerbari from the Minnow Support Project. It's a witness project run by aggroed, ausbitbank, teamsteem, someguy123, neoxian, followbtcnews, and netuoso. The goal is to help Steemit grow by supporting Minnows. Please find us at the Peace, Abundance, and Liberty Network (PALnet) Discord Channel. It's a completely public and open space to all members of the Steemit community who voluntarily choose to be there.

If you would like to delegate to the Minnow Support Project you can do so by clicking on the following links: 50SP, 100SP, 250SP, 500SP, 1000SP, 5000SP.

Be sure to leave at least 50SP undelegated on your account.

That is a really good look at the insides of that place. So much goes on to make some of the simple things we use each day. People really do live in a world of magic as so few take the time to learn how things work. Thanks again for sharing and congrats on getting to work there again. It looks like you learned a lot.

!sbi @shaheerbari