FT Rebuttal: Part 3 - Assessing Make In India

Authored by jain and govil - astute political observers

FT Rebuttal: Part 3 - Assessing Make In India

Modinomics is yet to deliver – was the Op-ed written by the Editorial Board of Financial Times published from London -(https://twitter.com/ft/status/1069894756929585152. They have raised the following issues in the article.

- Modinomics yet to deliver to many (https://steemit.com/financialtimes/@ajain/ft-rebuttal-part-1-assessing-how-modinomics-has-reached-the-poor)

- Failed infrastructure overhaul (https://steemit.com/india/@ajain/ft-rebuttal-part-2-assessing-failed-infrastructure-overhaul)

- Failed attempt to turn country into a manufacturing powerhouse

- Demonetisation ineffective

- Economic growth squandered away on symbolic projects (Statue of Unity)

- Fudging statistics

- NPA’s (Non-Performing Assets of Banks)

- RBI Fracas (Reserve Bank of India)

We have initiated a series of eight articles where each issue raised in the Financial Times Op-ed as listed above, will be taken up and put under the microscope of facts and data to critically test the validity of the statements made. In the first two articles, we have covered the first two points - ‘Modinomics has yet to deliver to many in India’ (https://steemit.com/financialtimes/@ajain/ft-rebuttal-part-1-assessing-how-modinomics-has-reached-the-poor), and, ‘Failed infrastructure overhaul’ (https://steemit.com/india/@ajain/ft-rebuttal-part-2-assessing-failed-infrastructure-overhaul). We also saw through the prism of data that both these statements are nothing short of a canard being spread. In this article, we will test the statement – Failed attempt to turn country into manufacturing powerhouse.

The Op-ed makes a sweeping statement that government failed in its attempt to make India a manufacturing powerhouse. Such kind of ill-informed statement can be expected from a political publication. However, it is quite a sorry state of affairs when this kind of a statement comes from the Editorial Board of a leading Financial Daily of international repute (Crème da la crème). They should be fully aware that India has progressed well on Make in India front. In this article, we have an in-depth look on Make in India and assess through facts and data what have been the results.

We begin our analysis by examining the structural changes made by the Modi government toward enabling an environment for ‘Make in India' and unleashing its full potential. Instead of drawing up our own framework, we will examine it using the international standards defined by World Bank and used to measure the business environment in a competitive format for 190 countries across the globe.

Known as ‘Doing Business', this is a flagship report of the World Bank and is in its 16th year in 2019.

The ‘Doing Business’ report deploys an exhaustive evaluation methodology making use of a multitude of factors to assess the ‘ease of doing business’ ecosystem within a country. The assessment is based on a well-defined point system to arrive at the final competitive standing for a country. The report not only allows you to know where a particular country stands in terms of its ranking (at each parameter level) and where all is a country facing challenges. For the government of a country, the report is an invaluable insight and third-party assessment as to areas to focus for improvement. ( http://www.doingbusiness.org/en/reports/global-reports/doing-business-2019 ). The factors on which the assessments are carried out by the World Bank are as follows:

• Starting a business

• Dealing with construction permits

• Getting electricity

• Registering property

• Getting credit

• Protecting minority investors

• Paying taxes

• Trading across borders

• Enforcing contracts

• Resolving insolvency

So where did India stand on doing business in 2014 and where does it stand today? This will be the clearest indicator of the contribution by the government of the day (in India’s case – Modi Government) towards evolving a manufacturing ecosystem. In India’s case a supportive environment for ‘Make In India’.

India, under Modi government, has worked diligently on the above mentioned points over the last few years. As a result, India's ranking improved substantially between 2014 to 2018. It moved from 134 in 2014 to 77 in 2018. This jump in rankings is extremely satisfying for the country. And, what is even more satisfying is the fact that India has shown a marked improvement in virtually all parameters affecting the business environment. The following chart shows how India has moved between different parameters (above listed points) between 2014 and 2018.

Studying the chart, one would observe that India has shown substantial/significant improvement on all factors except one – Registering Property. So, what has gone wrong with the Real Estate sector leading to its deterioration? Frankly nothing. On the contrary, the Real Estate sector is undergoing a ‘metamorphosis’ of sorts towards improvement. It is a well-known fact in India that this is the sector of the economy where maximum ills reside. Corruption, illegal construction, unaccounted money, unauthorized and illegal occupation, were all a way of life in this sector. The worst part was that politicians, builders, and bureaucracy, all acted hand in glove to create this unholy maze. The good news, of course, is that this sector is undergoing rapid cleaning up and is slowly resurrecting itself by having clean dealings and paying legitimate taxes. It is widely believed that commensurate with this cleaning up, businesses wanting to set up operations in India will find it easier to do real estate transactions for buying / renting premises for their business operations. The government is also considering reducing the tax burden on the property thus giving further impetus to fair and legitimate business operations. This change coupled with on-going improvements in the other factors will see India making giant strides and come up with much better ranking in the next few years. Perhaps may even reach the top 10 although reaching top 50 first may be a more prudent objective.

Let us see where India stands vis a vis China which has breached the Top fifty mark this year (doing business 2019 – the report is called 2019 but it pertains to data of 2018).

As can be seen from above, India has some ground to cover on almost all the factors. However out of the 11 factors there are 3 where India has its task cut out – Starting Business, Registering Property and Enforcing contracts (see the graph shaded with light orange). The first one is Starting Business. There was a labyrinth of processes that greeted an entrepreneur when starting on a new business. Since 2014 there has been a lot of emphasis on making the startup process friendlier and more efficient, but India still has to cover quite a distance. India needs to bring down the cost of starting a new business, the time taken and the number of hops one has to take in reaching the finish line. The next point – Registering property – is in the realm of ‘Real Estate’ which as we have seen above is already under scanner for a rejig and is responding to it also. The third one is ‘Enforcing Contracts’ which India will have to address sooner than later. India’s legal system and Judiciary has been a holy cow so far, and, it is commonly felt that Judicial reforms are the crying need of the day. India will have to undertake that to support India’s march towards progress. On the other hand, there are however some positive sides also vis a vis China. Much to the chagrin of pseudo seculars and the leftist media, India’s rating is significantly higher on Protecting Minority Interests. Actually, India stands among the top ten nations on this factor. Not just ahead of China but also ahead of UK, USA and the entire set of European countries (See the graph shaded with light blue). Another important parameter where India scores significantly higher vis a vis China is on the front of ‘Getting Credit’ (again see the graph shaded light blue). And this despite all the negatives of the NPA’s and RBI fracas (more on these two points in article 7 and article 8). India is among the top 25 nations on this parameter.

The question is – how does all this matter? It would be relevant to point out here that China, which is today acknowledged worldwide as a manufacturing powerhouse, started its journey some 47 years back. It started with Kissinger's secret visit to China in 1971, during the Nixon regime. But it was only after 2001, after China joined the World Trade Organisation, that ‘Made in China’ label started appearing more and more globally and China started showing the GDP growth rates of 9% plus. One can thus safely say that it certainly took China two decades plus to reach the state of being known as a manufacturing powerhouse. How misplaced then is the Editorial Board’s assessment to call Modi’s efforts (Make in India) as a failed attempt to turn country into manufacturing powerhouse when India has embarked upon this journey only 4.5 years back. The opinion of editorial board smacks of a prejudiced mindset. Specially given the fact that as per World Factbook report of 2018, on the front of industrial production, India with a growth rate of 7.5% stands tallest among all the trillion-dollar economies (https://en.wikipedia.org/wiki/List_of_countries_by_industrial_production_growth_rate)

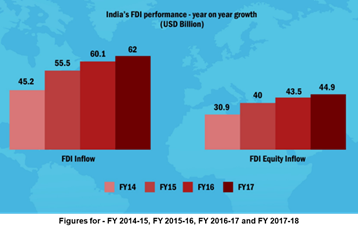

The story does not end here. Results on the ground support the analysis carried out above. Make in India has attracted significantly higher FDI into the country. As per figures released by Government of India the FDI into the country for FY 2017 – 18 was $ 62 billion. In fact, India has shown a consistently high FDI since 2014 when the Modi government came to power. See the graph below:

The importance of this should not be underrated. As per the United Nations Conference on Trade And Development (UNCTAD) there has been a considerable slowdown in FDI's across the globe. As per their data, the Global FDI fell as sharply as 41% in the first half of 2018 (calendar year). In the context of the UNCTAD report, for India to maintain its previous years FDI, and to show a marginal increase over it, is a big achievement in 2018. However, due to a global slowdown, the year 2019 is expected to see sharp declines in FDI’s across the globe. India will also likely to see a downturn in FDI. But the downturn is expected to be less compared to developed countries and many developing countries of Asia, like Hong Kong.

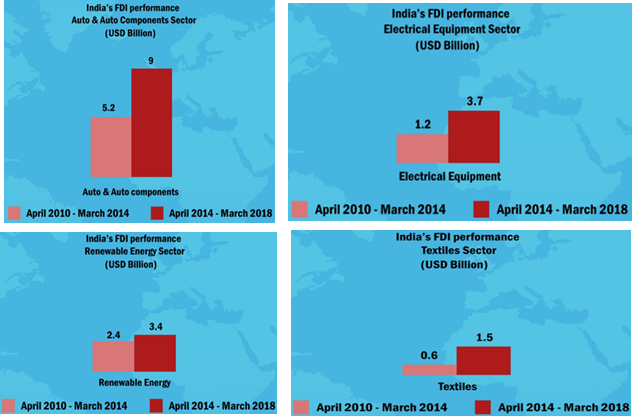

Moving on, we present below the FDI picture with respect to some of the leading industries.

Which are the major projects that have been set up or upgraded under ‘Make in India' programme? In the second article on Infrastructure, we saw some of the projects in Railways that have been set up under record time in India – 12,000 HP Electric Locomotives, Train 18. Another significant Make in India push in Railways was the factory to manufacture railway coaches near Rae Bareilly, an important and significant city in Uttar Pradesh. The factory was set up in 2011 but showed sub-optimal performance until 2014 with only 218 coaches being manufactured in the first three years. Modi government identified the factory for major revamp under ‘Make in India' initiative and since then almost 2,000 plus coaches have been manufactured in the factory in the last 3 years until 2018. A major expansion is planned to further enhance and upgrade the manufacturing capacity and technology. In a major technological thrust, the factory is being upgraded to produce aluminium coaches capable of running at speeds up to 250 km per hour. The capacity is also being enhanced to manufacture 5,000 coaches per annum. See the difference - from less than 100 coaches per annum to 5,000 coaches per annum.

Let us see some of the other major projects that have been set up or are announced:

BOEING – USA

Boeing and Tata Advanced Systems Limited (TASL) have signed a framework agreement to collaborate in aerospace and defense manufacturing and potential integrated systems development opportunities, including unmanned aerial vehicles. The companies intend to access markets jointly for products and platforms developed together by Boeing and TASL.

As a first step, a centre to manufacture aero-structures for AH-64 Apache helicopter has been set up in Hyderabad. The construction of the manufacturing facility began in 2016 and was completed a year later in 2017. This facility will be the sole global producer for fuselages of AH-64 Apache helicopters. Deliveries have already commenced from this facility with the first delivery being made in June 2018, within a year of the facility going live. A big achievement.

BMW – Germany

The luxury car brand owner BMW is well known across the globe. BMW has been in operation in India since 2006. Under the Make in India programme, BMW has decided to increase its localization to 50%. BMW has already signed deals with approximately 20 companies who supply its components. BMW will source door panels and wiring harnesses, exhaust systems, air conditioning and cooling modules, and seats from local Indian companies.

As per Mr. Vikram Pawah, president, BMW Group India, the company will start selling ‘Made-in-India' MINI Countryman from June and the production of the same will begin soon. After localizing 8 of its products (around 50% localization), the German luxury car major has decided to localize its iconic brand — MINI — with the beginning Countryman. (statement made to press in March 2018).

BSH – Germany

Source: https://www.bsh-group.com/se/newsroom/press-releases/bsh-inaugurates-technology-centre-in-india

The €14-billion BSH Group will invest an additional €100 million in India to set up a refrigerator manufacturing facility at its manufacturing campus at Sriperumbudur. This will also include establishing a technology centre, marketing and brand building. The company, on May 31, laid the foundation for a new refrigerator factory at its 44-acre facility near Chennai, where it had already invested about €100 million in 2015 to manufacture washing machines. “The additional investment is our commitment to the “Make in India” programme and serve the demands of the fast-growing India market,” Michael Schollhorn, Chief Operating Officer, BSH Hausgerate GmbH, told the press (3rd June 2018 -https://www.thehindubusinessline.com/news/bsh-group-to-invest-100-m-on-chennai-unit/article24073282.ece).

Gunjan Srivastava, Managing Director & CEO, BSH Household Appliances Manufacturing Pvt Ltd, said – “Refrigerators from the plant will hit the markets from 2021. We are aiming for an annual capacity of five lakh for both India and export”.

Samsung – South Korea

Samsung inaugurated their second factory in India. “Our Noida factory, the world’s largest mobile factory, is a symbol of Samsung’s strong commitment to India, and a shining example of the success of the Government’s ‘Make in India’ programme. Samsung is a long-term partner of India. We ‘Make in India’, ‘Make for India’ and now, we will ‘Make for the World’. We are aligned with Government policies and will continue to seek their support to achieve our dream of making India a global export hub for mobile phones,” said Mr. HC Hong, Chief Executive Officer, Samsung India.

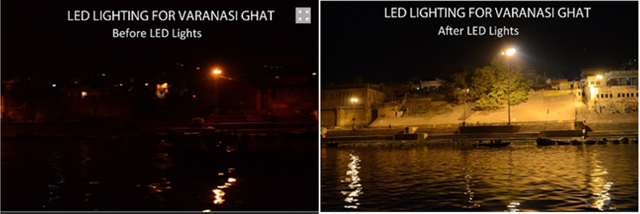

Energy Efficiency Services Limited (EESL) – India

This is a classic case of defining a business with an all-around win-win. As part of the commitment to reduce the carbon footprint in India, the Modi government embarked on a mission of replacing all traditional lighting with LED lighting. The government took lead in replacing the lighting in a phased manner in public utilities. The government facilitated manufacturers within India and from abroad to manufacture the LED lighting in India driving their prices lower due to bulk purchases. As the scheme rolled out the government announced attractive plans to enable households across India to buy the LED lighting at fraction of down payment and pay for the balance on a monthly basis through their energy bills. The cost may well get absorbed also due to a reduction in electricity consumption depending upon the usage. The target was to replace 770 million incandescent bulbs in India with LEDs manufactured under Make in India programme locally.

India has come to be referred to as the LED capital of the world. (http://pib.nic.in/newsite/PrintRelease.aspx?relid=161768). The success of LED efforts in India prompted the government of India to push EESL to take the highly successful mission to the UK. EESL targets to replace 1 million inefficient lamps with LED bulbs in the UK, covering ten million households. (http://timesofindia.indiatimes.com/articleshow/58662726.cms)

In addition to some of the ones mentioned above India has signed large agreements for Defense manufacturing with other countries. With Russia, we have entered into an agreement to manufacture Naval Frigates, KA-226T twin-engine utility helicopters, Brahmos Cruise Missiles.

In addition, Hindustan Aeronautics Limited (HAL) has also signed agreements with Russian firms to transfer technology for the manufacture of Sukoi su 30MKI fighter jets. This will not only enable India to better serve its own fleet of Sukhoi Jets but also sell components to other countries who operate Sukhoi fighter jets as part of their fleets. All this got a shot in the arm when India entered the Missile Technology Control Regime (MTCR) in 2016.

The Make in India portal lists out a large number of agreements signed with different companies for setting up manufacturing facilities in India or enhancing their existing manufacturing facilities. For those who would like to study this in greater details the data is available on this link - http://www.makeinindia.com/investor-desk (go to marquee investments).

To ignore all this data, and, to ignore the fact that it takes more than a decade or two to transform the scenario (we have seen above that China took more than two and half decades), shows a mindset where statements are made without data support, and/or, data is ignored to suit the narrative of a prejudiced mindset. The editorial board’s statement holds no validity whatsoever. It is pathetic that a paper of the repute of Financial Times comes up and makes a sweeping charge with extremely thin or no data line support.

=====

We work hard to research the topic and collect data points to form a narrative. So, if you like the article please upvote, resteemit and leave a comment.

More supporting data for India growth projections:

https://www.foxbusiness.com/economy/this-could-be-the-worlds-biggest-economy-in-2030

A must read.

source for industrial growth rate data : https://en.wikipedia.org/wiki/List_of_countries_by_industrial_production_growth_rate