FLUID MECHANICS - PUMP PERFORMANCE

.jpg)

Background

Fluid mechanics is a discipline part of the field of applied mechanics that examines the behavior of liquids and gases in a stationary or motion state. The theory of fluid mechanics is closely related to the fluid.

what is the fluid?

fluid can be interpreted as a liquid. But in reality not all liquids can be categorized as fluids. In particular, fluid is defined as a substance that deforms continuously as long as it is affected by a shear stress. One of the discussions of fluid mechanics is the fluid dynamics we will discuss more specifically in this paper is pump performance.

What is a pump ?

A pump is a machine that adds energy to the liquid in order to increase the pressure or move the liquid through a pipe. pump can be divided into 2 types.

- Centrifugal pump.

- Positive displacement pump.

I will discuss about Centrifugal Pump

Formulation of the problem

History and Development of Centrifugal Pumps

Centrifugal pumps are the top choice of engineers in pump applications. Centrifugal pump is very simple and versatile. centrifugal pump was introduced by Denis Papin 1689 in Europe and developed in the United States in the early 1800s. At first this pump is known as Archimedean propellers. And initially the majority of pump applications use positive displacement pump.

- The first centrifugal pump is made

image source

The Basic Theory of Centrifugal Pumps

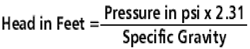

- A-1 Head

The pressure of a fluid can be assumed as pressure on a vertical column containing fluid, because the weight effect gives pressure comparable to pressure at all points. This column height is called a static head and is displayed in the terminology of feet or meters. . The static head over a given pressure depends on the weight of the fluid.

formula

A centrifugal pump creates a fluid velocity. This velocity energy is then transformed to the pressure energy when the fluid is released from the pump. head that is created can be said to be proportional to the energy of impeller speed.

formula

H= Total head in feet or meters.

v= Impeller speed in feet per second.

g= 32.2 Feet / Seconds

We can estimate the head of a centrifugal pump by calculating the impeller speed and put it in the formula above.

The formula that can be used for such speed

D= Impeller Diameter in inches

V= Speed in feet / sec

That is why we must always base on the understanding of fluid heads in feet / meters and not on pressure, when facing the centrifugal pump. A pump with an impeller type and with a speed, will raise the fluid at a certain height without regard to the weight of the fluid.

An identical pump will be able to serve fluids of varying degrees of viscosity.

image source

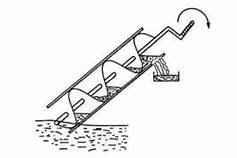

Suction Lift:Indicates the amount of Static Head in a pumping system where the Pump is located in a higher position from the suction Tank. (Static Suction Head)

image source

Suction Head occurs when the source of supply is above the pump's center line. So Static Suction Head is the vertical distance in feet or meter from the center line of the pump to the height of the pumped fluid.

Suction Head : Menunjukkan Static Head di sebuah sistem pemompaan dimana Pompa terletak lebih rendah dari Tangki hisap. (Static Suction Head)

image source

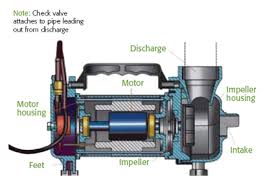

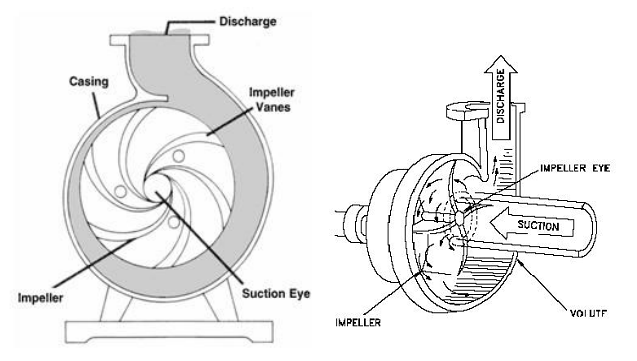

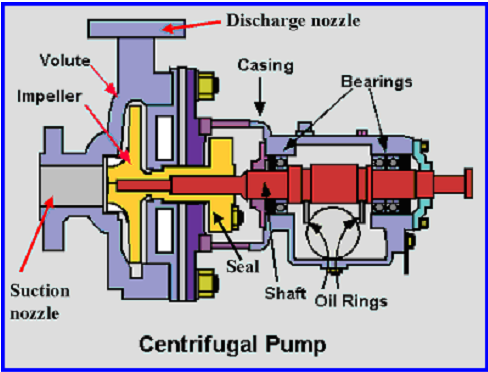

The main elements of the centrifugal pump

Broadly speaking the main elements or components of the centrifugal pump.

Parts of Centrifugal Pumps

image source

Impeller

Impeller is a round disc of metal with a path for fluid flow already installed. Impellers are usually made of bronze, polycarbonate, cast iron or stainless steel, but other materials are also used. As the performance of the pump depends on the type of impeller, then it is important to choose a suitable design and get the impeller in good condition. The number of impellers determines the number of stages of the pump. The single stage pump has one impeller and very suitable for head service (= pressure) low. The two-stage pump has two impellers mounted in series for a moderate head service. The multi-stage pump has three or more impeller mounted series for high head service.

- There are several impeller groups

- The main direction of the flow from the rotation axis:radial flow, axial flow, mixed flow.

- Types of suction: single suction and double suction.

- Mechanical shape or construction

- Various kinds of impeller

- The closed impeller

- Impeller open and semi open

- Pumped / vortex pump impeller

Pump Casing

The main function of the casing is to close the impeller on suction and delivery at the tip and so the tank-shaped pressure. The pressure at the suction tip can be as small as 1/10 atmospheric pressure and at the sending end can be 20 times atmospheric pressure at a single stage pump. For multi-stage pump the pressure difference is much higher.

- pump casing is designed for

- Provides ease of access to all parts of the pump for inspection, maintenance and repair.

- Create a leak-proof container by providing a box of jamers.

- Connecting suction pipe and delivery to flange directly.

- Easily mounted easily to a driving machine (electric motor) without loss of power.

Back Plate

Back plate is made of metal where with the pump casing to form the liquid room for fluid to be used as pressure.

Mechanical Seal

Connection between shaft motor rod/pump and the pump shell is protected by a mechanical seal

Shroud and Legs

Most types of pumps are tried with shourd and legs which can be set. Shroud is limited to muffle noise and protect the motor from damage.

Pump Shaft

Most pumps have cut rods placed on the motor to combine pressure, abolish the use of keyways. The assembly of cut rods can be simply designed, it still guarantees method direction to reduce noise and vibration.

Adaptor

Most pumps with an IEC standard electric motors. The connection between the motor and the backplate is connected by an adapter which conforms to IEC or C-frame standards of electronic motors.

Klasifikasi Pompa Sentrifugal

Capacity

- Low capacity <20 m3 / hr

- Medium capacity 20 - 60 m3 / hr

- High Capacity> 60 m3 / hr

Pressure Discharge

- Low Pressure <5 Kg / cm2

- Medium pressure 5 - 50 Kg / cm2

- High pressure> 50 Kg / cm2

Impeller Amount and Level

- Single stage: Consists of one impeller and one casing

- Multi stage: Consists of several impeller series arranged in one casing.

- Multi Impeller: Consists of several impeller arranged in parallel in one casing.

- Multi Impeller - Multi stage: Multi-impeller and multi-stage combination.

Axis Position

- Right shaft

- Horizontal axle

Number of Suction

- Single Suction

- Double Suction

Outflow direction of the impeller

- Radial flow

- Axial flow

- Mixed fllow

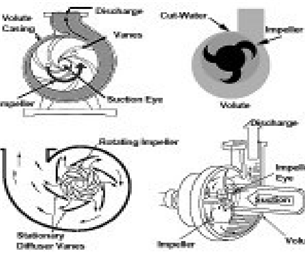

Working Principles of Centrifugal Machines

Centrifugal pump has an impeller (vane) to lift the liquid substance from the lower place to the higher place. External power is given to the pump shaft to rotate the impeller in the liquid.

On the outer circumference of the fan, liquids flowing in the pump house with pressure and speed. In this pump house the liquid is channeled in such a way, so there is a change of velocity into perfect pressure. The liquid column in the fangs is driven. This liquid moves in an unbroken flow from the suction channel through the pump to the canal.

working principle of pump

image source

Centrifugal Pump Protection System

In order for the pump to operate properly, there is a standard protective procedure applied to the centrifugal pump.

- Protection against backflow.

- Protection against overload.

- Protection against vibration.

- Protection against minimum flow.

- Protection against low NPSH available.

Use of Centrifugal Pumps

In the daily life of many centrifugal pumps provide a great variety of benefits for humans, especially in industry. Secara umum pompa sentrifugal digunakan untuk kepentingan pemindahan fluida dari satu tempat ke tempat yang lainnya

- some other examples of centrifugal pump utilization

- In the petroleum industry.

- In the shipping industry.

- Warman centrifugal pumps specially designed to pump mud, chemical material, and all liquid solutions mixed with solid particles.

- Centrifugal and reciprocating pumps RUHRUMPEN for various types of applications.

Advantages and Disadvantages of Centrifugal Pumps

In some cases the use of centrifugal pumps, this pump provides better efficiency than the displacement type pump. This is because this pump has the advantage of other pumps.

- Excellence

- The working principle is simple.

- It has many types.

- The construction is sturdy.

- There are various types of water discharge output capacity options.

- The drive shaft can be directly connected to the pump.

- Less need of space.

- The road is calm, so the foundation can be made light.

- The efficiency is good.

- Can be used for high temperatures.

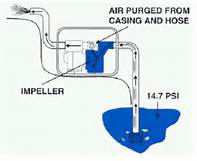

- Centrifugal also has weaknesses

- Under normal circumstances a centrifugal pump can not suck itself (can not pump water).

- Less suitable for working viscous liquids, especially on small volume streams.

- No self priming, although with a special design can be made into self priming.

- Not suitable for small capacity

Conclusion

- Centrifugal pump was first made in 1689 by Denis Papin in Europe and developed in the United States

- centrifugal pump consists of several main components such as, impeller, casing pump, Back Plate, , Mechanical Seal, Shroud and Legs, Pump Shaft, adaptor.

- Centrifugal pump protection system consists of, protection against backflow, protection against overload, fibration, minimum flow, and protection against low NPSH available.

- The benefits of centrifugal pumps are widely used in industry,such as petroleum, shipping.

- Centrifugal pumps are superior to other pumps in some respects.

Reference

http://bpompa.blogspot.com/2009/09/sejarah-pompa-sentrifugal_04.html

http://begokmild.com/2010/03/pompa-sentrifugal/

http://www.scribd.com/doc/27804524/pompa-sentrifugal#

http://industrikimia.com/tutorial/mengenal-komponen-dalam-pompa-centrifugal

http://cheresources.com/centrifugal...s3.shtml

http://me-poltekkapal.info/2010/04/analisis-pompa-sentrifugal/

happy to share, if you like my article follow me @feryhusaini

Congratulations! This post has been upvoted from the communal account, @minnowsupport, by fery husaini from the Minnow Support Project. It's a witness project run by aggroed, ausbitbank, teamsteem, theprophet0, someguy123, neoxian, followbtcnews, and netuoso. The goal is to help Steemit grow by supporting Minnows. Please find us at the Peace, Abundance, and Liberty Network (PALnet) Discord Channel. It's a completely public and open space to all members of the Steemit community who voluntarily choose to be there.

If you would like to delegate to the Minnow Support Project you can do so by clicking on the following links: 50SP, 100SP, 250SP, 500SP, 1000SP, 5000SP.

Be sure to leave at least 50SP undelegated on your account.

👍👍👍👍👍