Rubber Industry - The Crying Tree

Hi Steemians, today I am gonna talk about rubber manufactoring industry, which has many strategic positions in daily life. It is a very open industry especially for entrepreneurship. Even the culls does not go to waste during the production process, even sold to related companies at very good prices. However, bad side is if you are preparing zero rubber dough mixes, then you will be especially involved with that black powder that named black carbon.

If the ventilation and operating conditions are fully established, you do not need to be too afraid of this powder. At the same time, if the company has the rubber dough in the process of cooking and pressing, it means you are still at risk. Plastic and rubber products have an important place in the chemical sector. Rubber keeps its popularity because of the use of many areas in our daily life. Now let's talk about the basics about what a little rubber is.

Rubber is actually a tree name. The name of the rubber comes from the language of the locals in the Amazon region (caoutchouc = crying tree). The material obtained from the tree itself or from latex is used in the industry. Since natural rubber is used so much, synthetic rubber was obtained in 1906 in order to obtain rubber in abundant quantity and cheap. Many types of rubber have emerged in recent years. The most important feature of rubber is that it has high elasticity. This is also the basis for the development of the rubber industry. Waterproof cloths were produced by drying between latex cloths. Rubber first started to be mentioned in 1530s. The earlier was unknown.

Over 12 tonnes of rubber are produced, of which about one-third are natural rubber all over the world. The rest is the synthetic rubber made from the chemical substances obtained from petroleum. The natural rubber is obtained from the latex of the rubber tree (hevea brasiliensis). The best areas of this tree are the sphere of the equator. There are few industry where rubber is not used. Most of the 60% of the produced rubber is used in the production of many tires from bicycle tires to the tires of work machines.

Tire is a material obtained from the combination of petroleum and alcohol obtained from natural latex of some tropical plants together with rubber raw material. The rubber, which was defined by scientists in southern america in 1736 and was vulcanized by Charles Goodyear at the beginning of 1840, has taken its place in the industry since then and has gained commercial importance.

Goodyear's method has been developed over time with the addition of certain chemicals to accelerate the sulphurisation process and to enhance the resistance of the rubber against breakage. Rubber the most basic raw material of rubber dough is never used alone. Generally, a tire hull contains 50% by weight of rubber. The tire was first obtained by sulfur + rubber, and because of the importance of the latter, foreign substances were added to the tire to improve it. The most important inputs of the tire industry are natural and synthetic rubber and carbon black. The user demanding the output of the tire industry is the automotive industry. In times of crisis in the automotive industry, the tire sector is also naturally affected.

Usage Areas

The rubber has a wide range of uses. It varies from semi-finished products to finished products. Vehicle tire sector is the most rubber consuming sector with almost %60. Some of the other products where the rubber is extensively used are belt conveyor, belts, hoses, gaskets, treads and bellows... Medical and industrial products are also rubber products. Besides various types of adhesives are also produced from rubber. When you are thrown into the rubber sector, the tests you might encounter in each department are,

- Hardness, Shore A, IRHD

- Density

- Rheometer

- Split- stretch

- Delaceration

- Permanent deformation

- Ageing tests

- Ash

Technical Rubber Knowledge

Rubber

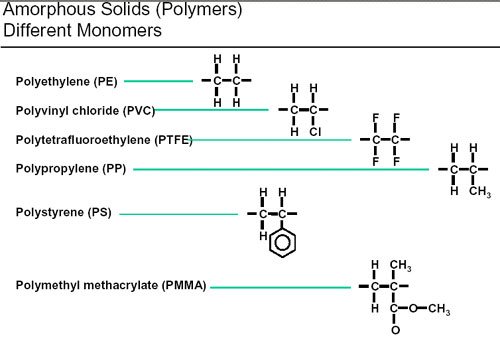

Polymer and monomer concepts: Plastics and rubbers fall into a class of compounds identified by the name of polymer (macromolecular). Polymers are very large molecules formed by covalent bonds of small molecules called monomers.

Monomer

CH2=CH-CH=CH2 ; butadiene (gas)

Polymer

( CH2-CH=CH=CH2 )n ; elastomer (solid)

A polymer chain is a large chain of molecules formed by the bonding of a large number of monomer molecules. Depending on the type of atoms, the polymer chain has a certain mobility. The monomers used to bring the polymer molecule to the operation must have two or more functions. The following molecules are monomers with two functions.

The two functional monomers form a straight chain. One R radical forms a straight chain PVC (polyvinylchloride) from vinyl chloride monomers. If the monomer molecule has three or more functions, branching or cross-linking occurs. The polymer chains may be as follows,

- Straight chain structure

- Short-branched chain structure

- Long-branched chain structure

- Cross-linked chain structure

- Star structure

- Comb structure

Elastomers

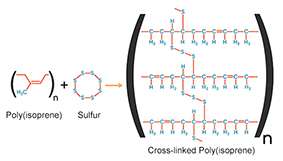

The elastomers we have described as rubber are the network structure formed by sparse cross-linking of polymers. For polymers to be elastomers, they must have high molecular weight, low strength between chains, random chain structure, and cross-linking properties.

Rubber Concept

Rubbers are non-crosslinked but vulcanizable polymers. It exhibits a dark liquefied flux under high temperature and under the influence of deforming forces. So they can be shaped under favorable conditions. The tire concept is the same as the elastomer concept described above.

The ability to crosslink can be explained by vulcanization. Vulcanization is the change of the chemical structure of the rubber and it comes to a condition that has elastic properties irreversibly. High plastic properties before vulcanization leave high elastic properties after vulcanization.

Rubber Mixture

It is a vulcanizable mixture composed of rubber and other raw materials and additives adjusted to the desired properties. A prescription consists

- Rubber

- Fillers

- Plasticizers

- Process facilitators

- Anti-ageings

- Activators

- Accelerators

- Vulcanization system

- Retarders

- Other addivite materials

Vulcanization

The cross-linking property depends on the amount of the curing agent, the activity and the reaction time. This property is expressed as the degree of vulcanization and the cross-linking density. In the most common sulfur vulcanization, different cross-linking patterns can occur depending on the type and amount of other additives, especially the accelerators used. The properties of the vulcanized rubber are largely dependent on the shape and density of the cross-linking.

| Ingredients | Quantity (phr) | Function |

|---|---|---|

| NR | 100 | Natural rubber |

| Sulfur | 1.0 | Vulcanizer |

| MBT | 1.0 | Accelerator primer |

| TMT | 0.1 | Accelerator seconder |

| ZnO | 5.0 | Activator, inorganic |

| Stearic acid | 1.5 | Activator, organic |

| Carbon black | 40 | Strengthening |

| Mineral oil | 1.5 | Plasticizer |

| PBN | 2 | Antioxidant |

| TOTAL | 152.1 |

This product was prepared according to 100 parts of rubber and shortened to phr (Parts Per Hundred Rubber). In this formula, the weight of the mixture and contents does not matter at all. The rate of mixing is determined by the raw rubber to be used.

img credz: pixabay.com

Nice, you got a 4.0% @minnowbooster upgoat, thanks to @kedi

Want a boost? Minnowbooster's got your back!

The @OriginalWorks bot has determined this post by @kedi to be original material and upvoted(2%) it!

To call @OriginalWorks, simply reply to any post with @originalworks or !originalworks in your message!

Congratulations @kedi, this post is the fifth most rewarded post (based on pending payouts) in the last 12 hours written by a User account holder (accounts that hold between 0.1 and 1.0 Mega Vests). The total number of posts by User account holders during this period was 1880 and the total pending payments to posts in this category was $1789.22. To see the full list of highest paid posts across all accounts categories, click here.

If you do not wish to receive these messages in future, please reply stop to this comment.

All polymer we can make a shorten with Poly6, hehehehe

haha yep its possible