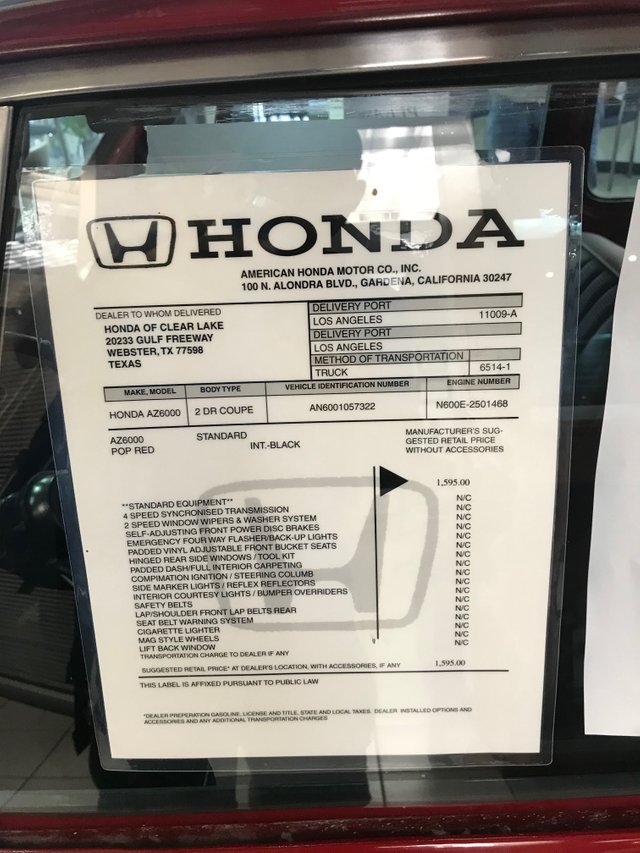

1972 Honda Z600 $1595 Small But Mighty and Its Link to Clinical Quality Improvement

I took these photos today while I was waiting to have my Honda serviced. Every time I see this car, it reminds me of my work in clinical quality improvement. Why? The first part of the answer is that by looking at this car it is easy to see why many in the US scoffed and joked about the early Japanese imports. At the time this was sold, most popular US vehicles were large "land yachts." In fact, my first car just out of high school was a 1973 Chevy Impala. I seem to remember that the hood and trunk were each longer than the interior. But the import cars were mighty, not because of their size, but because of the processes that were engineered to build quality into them.

If you just want more photos, just scroll to the end. The rest of the text is about quality improvement.

Fast forward around 10 years to 1980 and the imports that so many joked about were so much higher quality than the US cars that US auto manufacturers started looking to Japan for help. Many of us know this story, but I doubt many know how Japan was able to overtake the industry that the US once dominated. Japan's success came about because many of the engineers and their managers adopted the methods of Dr. W. Edwards Deming, a US professor of statistics and math who was a big proponent of Shewart's statistical quality improvement approach.

The US government called Deming to Japan twice to help them apply these methods to rebuild the country after WWII. Then in 1950 Deming was invited to teach statistical quality improvement to the Union of Japanese Scientists and Engineers. (See The Deming Institute: Timeline) The Japanese engineers and managers embraced his work, leading to much higher quality products at lower costs.

The key to statistical quality control is to use statistical methods (many of them extremely simply) to analyze and design manufacturing process to reduce variation. Parts that vary too much add up to lower quality, as do parts that break down too much. A bolt that is supposed to be exactly 1mm in diameter is never exactly right, but if the variation is small enough for the application the part will work well. Statistical quality control works by identifying sources of variation in a process producing parts, such as bolts. Once identified those sources can be studied and eliminated.

The Link to Clinical Quality Improvement?

This same approach is now used for clinical quality improvement, but just as some were slow to adopt the methods in manufacturing, the US healthcare system is still not making full use of the approaches. In almost every clinical dashboard I see (other than those I work on) data is presented without considering or presenting the effects of random variation. A clinic's performance on a specific metric (say percentage of patients with controlled blood pressure) is compared to other clinics without considering (and in many cases even presenting) the number of patients each clinic's "performance" is based on. Think about it, if you flip a coin twice and get two heads, you would not think anything is unusual about the coin, but you flipped it 1000 times and got 1000 heads, you'd be sure to examine the coin closely. Shewart and Deming's methods allow us to detect when variation that we see is simply random or due to some specific assignable cause. They then provide methods for reducing that variation, regardless of which type it is. Ignoring these methods tends to result in blaming and shaming individuals for what are actually poorly designed processes combined with expected random variation. Its like firing the person who flipped a coin 10 times and got only 5 heads, because their coworker flipped the same coin 10 times and got 8 heads. Instead of firing someone, you really need to get a coin that produces more heads when flipped.

Here are more photos of the car.

Go here https://steemit.com/@a-a-a to get your post resteemed to over 72,000 followers.

World of Photography

>Visit the website<

You have earned 6.50 XP for sharing your photo!

Daily photos: 1/2

Daily comments: 0/5

Multiplier: 1.30

Block time: 2018-06-08T02:12:27

Total XP: 13.00/100.00

Total Photos: 2

Total comments: 0

Total contest wins: 0

Follow: @photocontests

Join the Discord channel: click!

Play and win SBD: @fairlotto

Daily Steem Statistics: @dailysteemreport

Learn how to program Steem-Python applications: @steempytutorials

Developed and sponsored by: @juliank