Applied & Industrial Microbiology (Microbiology #5)

Hi guys! I am back with another post related to microbiology - today I will be writing about the use of microorganisms in industry, with focus on fermentation.

This article will cover fermentation, bioreactors and all the stuff you need to think about when using them. And much more (maybe :D )!

Fermentation

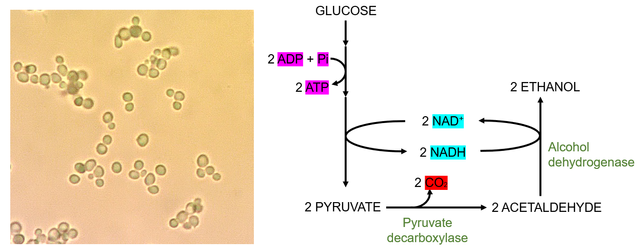

Fermentation is a process of turning carbohydrates such as sugars into ethanol by living organisms. An example of organism capable of utilizing fermentation is the budding yeast Saccharomyces cerevisiae (more about it HERE). During alcoholic fermentation (see scheme bellow) is glucose converted by process termed glycolysis to pyruvate (this creates ATP -> ATP = energy) which is later decarboxylated to acetaldehyde. Then is NADH oxidized and acetaldehyde is being converted to ethanol (with the help from enzyme alcohol dehydrogenase). The regeneration of NADH is important to keep glycolysis running as this is the only way the organism is able to generate energy (ATP). Energetic yield from one molecule of glucose is only two molecules of ATP- so not very efficient. But thanks to this process we have alcohol - beer, wine, everything! And in order to get these products we need a LOT of yeast cells.

Biotechnology is basically a branch of science that uses living organisms to make some kind of product (more about biotechnology HERE). Biotechnology encompasses several division that are distinguished by colour code. One of the branches, termed white biotechnology, focuses on employment of microorganisms in chemical production. Such as using budding yeast to create wine or beer. There are also other parts of biotechnology and microorganisms can be used to create enzymes, vitamins, etc- but in this article, I will focus on fermentation.

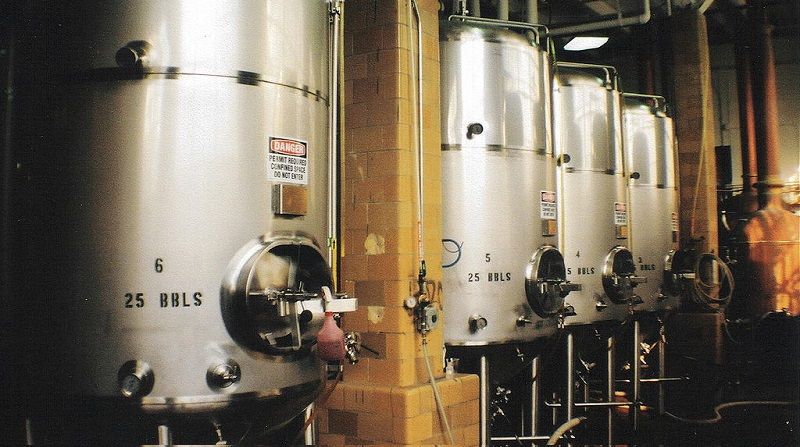

In a context of industrial microbiology and biotechnology the term fermentation refers to the growth of large quantities of cells under anaerobic (without oxygen) or aerobic conditions within a vessel called a fermenter or bioreactor.

Why not just using chemistry?

It is possible to employ purely chemical methods to create alcohol. But. Biotechnological process are commonly more ecological. Is that enough for us? No (sadly). Money is the thing that interests most people and the market value of identical chemical can be actually higher, if produced with biotechnology instead of purely chemical methods. Why? Well, there is something called the efficiency factor (E-factor) that is defined as kg of waste per kg of product. And the aim is to have more product and less waste. So probably in some cases it is better to use chemical processes, but mainly if the goal is to get great volumes of some compound industrial biotech is more preferable.

Source

Fermentation process and conditions

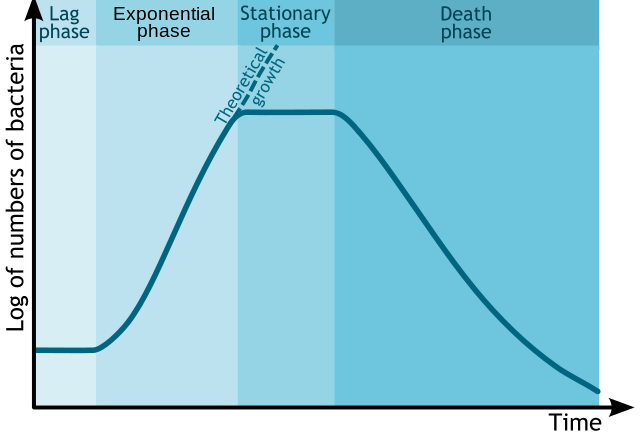

There are basically 4 phases of growth of microorganisms:

Source

Lag phase: Inoculation of medium with microorganism does not result in its immediate growth and takes a while.

Exponential phase: Microorganism has plenty of resources and divides exponentially - for a certain amount of time!

Stationary phase: At a certain point in time the growth does slow down and even remains constant without further increase- due to decrease in nutrients or increase in toxic substances.

Death phase: After certain time the decrease in available nutrients and accumulation of toxic substances may result in death of the cells. Contamination of culture may also cause this phase.

Fermenters

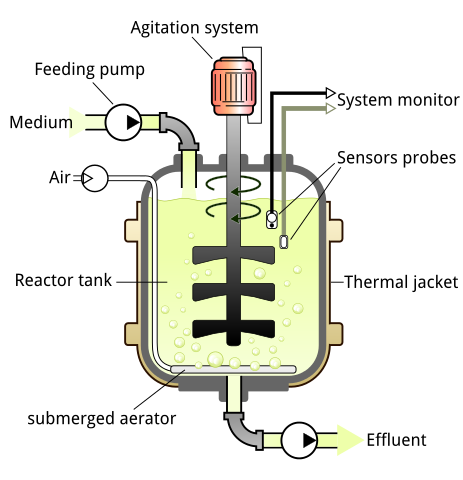

Also known as bioreactors are basically huge tanks with controlled environment that use microorganisms to produce some kind of product. We can basically divide them to three categories:

Stirred batch fermenter: It is a closed system in which all the nutrients are presented at start of fermentation within a fixed volume. This means that at the beginning of your fermentation process you put all the stuff inside the tank and close it without further interfering during the process. Biomass production limited only by nutrients and toxic waste substances. Cells are harvested when biomass levels or product levels start to decline.

Fed-batch fermenter: In this case you are adding fresh growth medium to the fermenter and the volume of batch increases with time. Initial concentration of growth medium is low and continuous addition of this medium eliminates the situation when growth is being inhibited by the depletion of nutrients. However, toxicity is still a problem.

Chemostat: Also known as Continuous culture. Here you add fresh medium as well, but you also remove old medium and cells. Thus, eliminating both limitations – lack of nutrients and accumulation of toxic products. Thanks to this it can operate continuously for months!

Schematics of a Chemostat, but in principle represents all types of bioreactors.

Source

Controlling growth conditions

It is also important to control the growth conditions in the fermenter. Let’s check it out!

Temperature: Critical for optimum growth. Also used to sterilize the system. It is also important to be able to cool the whole system, because heat is being generated due to stirring and metabolism.

Mixing: Used to maintain homogenous distribution of nutrients and temperature. Can promote foaming - which is not desired at all. Why? It causes loss of culture volume and increases the risk of contamination.

pH control: Well, many cell cultures have a specific range of pH they can grow in.

Aeration: Sometimes you want to have oxygen there, sometimes you do not - it depends. It is related to flow rate and stirrer speed and also dependent on temperature.

Fermentation media

In order to achieve optimal growth fermentation media have to satisfy all the nutritional needs of microorganisms. They need to contain:

Carbon source

Sources of nitrogen, phosphorus and sulphur

Trace elements and vitamins

Space time yield

I would like to end this article with mention of STY – space time yield. It is defined like this:

And the goal is to increase this value. Meaning that you want to have more product in the same conditions or decrease the production time and production volume. It would be best having both, haha.

Source

Concluding remarks

Soo, hopefully you did learn something new today! Many scientists do not like the application of science in profitable activities, or at least at my department. But I actually do not think there is something wrong about it. Heck, even here we are using our “scientific” knowledge to get money. And the truth is that many of those people studying biology might and will end in private sector or biotechnological companies.

Have a great day!

Previous parts of Microbiology series:

Part 1 - Virus, bacteria or yeast. What’s the difference?

Part 2 - Antonie van Leeuwenhoek – Father of Microbiology

Part 3 - Queen of fermentation – Saccharomyces cerevisiae

Part 4 – Escherichia coli – friend or foe?

References

Industrial fermentation – Wikipedia article

Industrial microbiology – Wikipedia article

Feldmann et al. – Yeast: Molecular and Cell Biology