ADDITIVE MANUFACTURING: MANUFACTURING WITH DIVERSE POSSIBILITIES.

When you mention the word manufacturing, what comes to mind are large industries with big machineries making unpleasant sounds. Of course that is where most of our daily products come from. These conventional manufacturing techniques includes casting and machining. But what if I tell you that the manufacturing industry is changing.

Would you believe if I say you could sit in your home and make various product of your choice? Imagine you making your own Nike shoes, producing your car spare parts or producing your engagement ring.

Do you know that Engineers can have their inventions come to live before them in quick time?

Do you know that hospitals can produce unique body implant for patients without leaving the walls of the hospital? Wouldn’t that be life-saving?

Sounds too good to be true, right? But you will agree with me that the advancement in technology today has made unthinkable things possible. Additive Manufacturing (AM) is a technology of such. It is a technology with diverse possibilities.

DEFINITION

Additive manufacturing (AM) is the fabrication of (or simply making) three dimensional objects using a digital system by the addition and accumulation of each layer of the object. The term 3D printing is often used interchangeably with additive manufacturing. The term 3D printing is more popular and is mostly used among hobbyists and persons alike. Among professionals, the term Additive manufacturing prevails.

ADVANTAGES OF ADDITIVE MANUFACTURING OVER CONVENTIONAL TECHNIQUES

Highlighted below are some of the ways in which AM surpasses these conventional techniques:

Improvement in supply chain

AM presents the possibility to enhance how manufacturers get their products across to consumers. With AM, manufacturers can make available their product by providing the 3D model file via the internet for customers to download and then 3D print on their own. This will limit the need for transporting products or the need for customers to travel in order to acquire their supplies and thus a “win-win” situation. It means I can simply replace a faulty part in my car by simply downloading the design from my car manufacturer and then have it printed by myself.Flexibility

With conventional techniques, modification in the design will require retooling which implies delay and additional cost. However, with AM, new design changes are quickly implemented without delay. Also, AM is suitable for manufacturing variety of products as it requires little or no changes in the setup unlike in conventional methods. Thus AM is suitable for one-off production.Sustainability

Conventional manufacturing techniques like machining are material removing processes. These methods remove excess material in form of chips and thus lead to material wastage. AM uses only the needed quantity of material and thus saves material. It usually employ material that can be recycled and reuse.Rapid Manufacturing

The speed of making a product via AM is unparalleled by most conventional techniques. Conventional means involve various steps to achieve the end product. Take for instance in the production of a gear. The part is first turned on a lathe and then moved onto a milling machine to cut the gear teeth before grinding to give it a good finish. Much complex products require more steps than this. However with AM, the part is usually manufactured in a single step. This has made AM useful in making prototypes as inventors and designers could have the prototype of their product in quick time.Reduction of upfront Cost

Although AM cannot replace conventional manufacturing like casting. It helps in the reduction of upfront cost. Molds for casting are conventionally made by machining operation which can be carried out using AM. This limits material waste and saves cost in machining.ADDITIVE MANUFACTURING PROCEDURE

The procedure in manufacturing an item using additive manufacturing is in three (3) steps which are discussed as follows:

- Modelling

Slicing

Slicing is the next step after making the model and converting it into an STL file. Slicers are the softwares used for the slicing operation in 3D printing. The slicer divides i.e. slice the 3D model into a very large number of thin slices or sections. Each slice or section is called a “layer”. At the same time the slicer generates a G-code (a numerical control programming language) which contains the instruction needed by the 3D printer to carry out the production of the item. Examples of slicers are: Slic3r, Simplify 3D, Repetier, Net Fabb, Ultimate Cura and so on.Printing

This is the final stage in Additive manufacturing. Here, each layer of the object made through slicing is formed in succession until the final piece is achieved. How this is done depends on the technique and printer employed. There are various techniques and a wide range of printer to choose from. A number of factors influence the final decision. Amongst them is cost (of 3D printer, material and technique), as well as the speed of manufacturing.

The American Society for Testing and Materials (ASTM) groups all 3D printing techniques into seven (7) categories. These will be discussed in the sequel of this article. However, to feed your curiosity, we are going to look at one common technique known as Fused Deposition Modelling in the next section.

It is noteworthy that in some cases, after printing, some finishing operations may be carried out.

FUSED DEPOSITION MODELLING (FDM)

Before I proceed, you should know that every 3D printer has a “head”. This head is where the raw material is processed and it is from there it is deposited in layers to form the objet intended. More on 3D printers will be discussed in the sequel of this article.

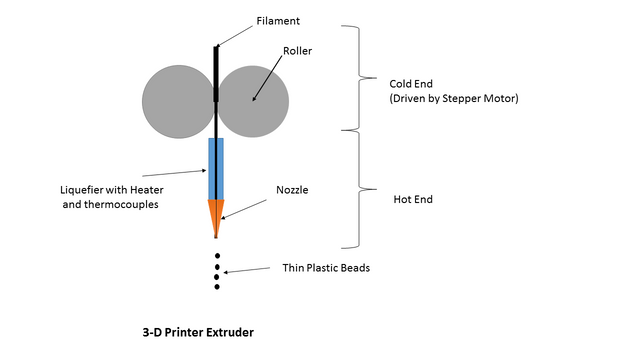

FDM also called Fused Filament Fabrication (FFF), is one popular technique in 3D printing. In this technique, the printer utilizes an extrusion type head (see the image to the left). Thus, FDM falls under the category of “Material Extrusion” 3D printing (These types of 3D printing are based on the principle of extrusion, where a large size material is forced through a smaller passage and thus comes out as a smaller size). The extrusion head is fed with a filament of a suitable material from a spool, which gets melted by heating and is then injected through a nozzle called the extrusion nozzle. The molten material is forced out of the nozzle to form each layer in succession. The layers later solidify and forms the required product.

MATERIALS FOR 3D PRINTING

If you are beginning to wonder about the kinds of material that can be 3D printed, then the answer to your question is “Any”. Yes, any kind of material can be 3D printed. The most common however are plastics such as acrylonitrile butadiene styrene (ABS), high impact polystyrene (HIPS), and poly-lactic acid (PLA). Metals such as steel, titanium, aluminium and so on are also usable. Precious metals like gold and silver are used to 3D print jewelries. Ceramics like porcelain are used to 3D print dishwares.

SOME AREAS OF APPLICATION OF 3D PRINTING

Medicine

3D printing has improved the quality of health care as specialists can now use 3D printing to make body implants and prosthetics (i.e. artificial body parts(see the first image) ).Automotive

Wikimedia Creative Commons: Koenigsegg One:1

The Automotive industry is one which has benefited a lot from the technology of 3D printing. An example is automotive manufacturers Koenigsegg. Their product known as “One:1” had some of its parts 3D printed using carbon fiber. They were able to save cost substantially and reduce production time considerably.Architecture

The field of architecture is one which is known to be among the earliest to use 3D printing. Architect use 3D printing to produce scale model of their designs for presentations.Sport

3D printing has enter into the world of sport, with renowned footwear and clothing manufacturer, Nike, 3D printing one of their line of boots known as Vapor HyperAgility Cleat. These boots helps to improve the agility of athletes. It also help to improve traction and aid in quick acceleration and deceleration as well as changing of direction quickly.Aviation

The Aviation industry is another sector which is known to have adopted 3D printing in making aircraft parts. An example is the American airplane maker, Boeing.CONCLUSION

Additive manufacturing is the production of a 3D product using 3D models. It is a superior manufacturing technique over the conventional means of manufacturing. AM has numerous capabilities and has reshaped many industries with these capabilities and in the process the productivity of such industries have been greatly enhanced. However, there is still room for improvement in the area of mass production as conventional means like casting is economical in that respect.Thanks for reading through. Do keep tabs on my articles as the sequel of this is upcoming. In the sequel, you will learn more about the types of 3D printers and techniques, Cost implications, Health and Safety issues, as well as more Applications of 3D printing.

REFERENCES

- 3D PRINTING.COM:What is 3D printing?

- 3D PRINTING.COM: Software for 3D Printing

- 3D Hubs: The Advantages of 3D Printing

- Pinshape Blog: Learn the Top Advantages of Additive Manufacturing

- Manufacturing.net : Top Five Benefits Of Additive Manufacturing (You Never Considered)

- Tinkercad Blog: 3D Printing Materials Guide

- Nike News:NIKE FOOTBALL ACCELERATES INNOVATION WITH 3D PRINTED “CONCEPT CLEAT” FOR SHUTTLE

- Wikipedia: Fused Filament Fabrication

- Wikipedia: 3D Printing

This is well written and very interesting. The engineers and the scientists are not waiting. Technology is really improving every aspect of our lives especially the computer.

I am waiting to start printing sbd and steem in my room 😂😂

Awesome effort buddy.... Technology will really blow our minds.... I'm so wowed at the numerous possibilities possible under this phenomenon.

Can I just print an apartment already?

Congratulations @temitayo-pelumi, this post is the ninth most rewarded post (based on pending payouts) in the last 12 hours written by a Dust account holder (accounts that hold between 0 and 0.01 Mega Vests). The total number of posts by Dust account holders during this period was 10608 and the total pending payments to posts in this category was $1736.42. To see the full list of highest paid posts across all accounts categories, click here.

If you do not wish to receive these messages in future, please reply stop to this comment.

Very good post temitayo-pelumi i appreciate your creativity, i want to become like you, a successful man and brand, i get inspired from your line.

Keep it up.. you can check my article about Updates to SC2 Pay - Enhanced Security and give me your feedback!

My article Updates to SC2 Pay - Enhanced Security